Shipping Conveyor Systems

Discover how FreightCenter makes shipping conveyor systems easy, affordable, and reliable. Learn about expert logistics, competitive rates, and personalized support for your shipping needs.

When people think about the word “conveyor,” they think of the moving staircases you ride on in multi-story buildings or shopping malls. But those aren’t the only conveyor systems out there; factories, warehouses, and other industrial buildings use different types of conveyor belts to move products, packaging, and other supplies throughout an area for manufacturing and distributing to retailers and consumers.

Shipping conveyor belts can be difficult, partly due to their size, intricate pieces, and metal exteriors. But at FreightCenter, we can move your conveyor systems as quickly and efficiently as your belts!

Whether you’re buying or selling, FreightCenter makes shipping conveyor systems easy and affordable. Follow the suggestions on this page, and you’ll see how.

We provide competitive freight shipping prices and an all-inclusive, easy-to-use shipping experience for our customers. Exceeding our customers’ expectations results in thousands of satisfied customer reviews and repeat business. We believe in the power of our customer relationships. Check out FreightCenter reviews from real customers, and learn what they have to say about their freight shipping experience!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

Why Choose FreightCenter for Shipping Conveyor Systems?

Expertise in Freight Shipping: With over 25 years in the logistics industry, FreightCenter is dedicated to guiding you through the entire logistics process, from beginning to end. Our goal is to make freight shipping easy to understand and book. Don’t waste time researching and receiving quotes from individual carriers- FreightCenter’s got your back!

Competitive Rates with Tailored Solutions: We prioritize high-quality customer service without breaking your wallet. We utilize our relationships with regional and national carriers to offer you competitive, affordable rates while providing personalized solutions to your needs. Need a liftgate? We got you! Want to expedite your order? Leave it to us! We’re ready to provide tailored solutions that don’t compromise your freight shipment.

Personalized Customer Support: FreightCenter is committed to satisfying our customers. Our friendly customer support team is here to help you every step of the way, from initial inquiries to post-shipment concerns. We handle all aspects of logistics, including tracking, paperwork, and communication with carriers, so you can focus on your business while we manage your shipment. Choose us for our reliable service and affordable quotes!

How to Ship Conveyor Systems

FreightCenter arranges shipping of all types of conveyor systems:

- Pneumatic conveyor systems

- Vibrating conveyor systems

- Flexible conveyor systems

- Vertical conveyor systems

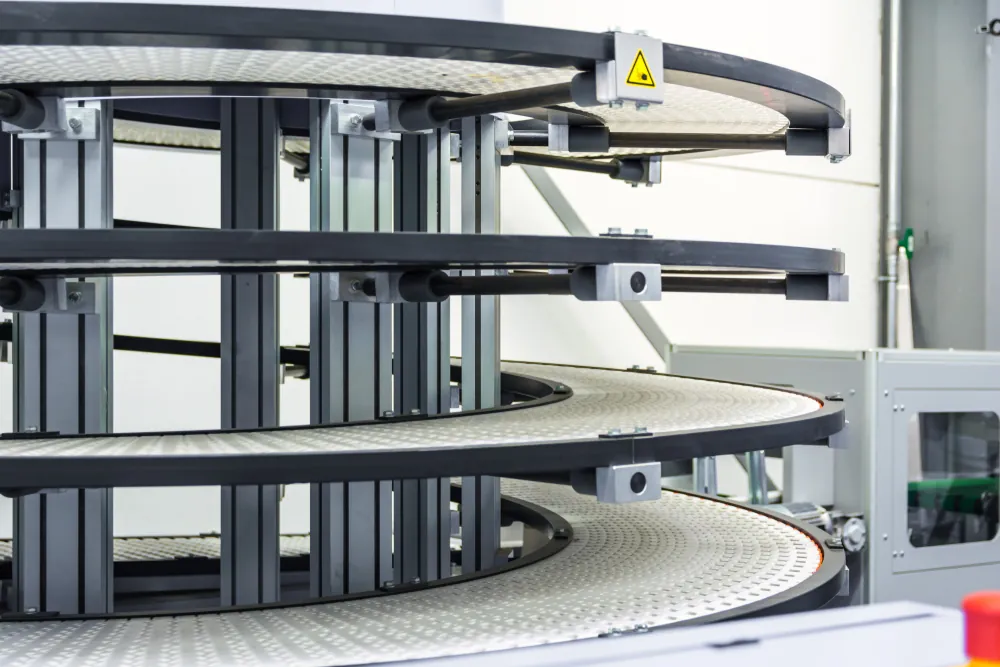

- Spiral conveyors

- Heavy duty rear conveyors

- And more …

All of these conveyor systems contain many parts, which can be easily lost during transport if they are not properly packaged. They also can get quite heavy, due to most of the parts being metal.

Shipping conveyor systems is best done via LTL (less-than-truckload) freight shipping. You save money with LTL shipping because your shipment shares the truck with loads from other shippers. Your cargo must be packaged so it will not be damaged in transit and will not present a danger to other shipments on the truck. If shipping your conveyor system requires a Full Truckload, out Truckload division will match your shipment with the right vehicle. Get started by generating an instant truckload quote. Our in-house experts will take care of the rest.

How to Compare Ltl Freight Shipping Costs From Trusted Carriers When Shipping Conveyor Systems

FreightCenter is where the best freight carriers compete for your business. We enable you to compare multiple carriers’ rates and expected transit times in seconds. You choose which carrier you want to handle your shipment. FreightCenter takes care of the rest. Your first step is to get an instant online freight shipping quote.

1) Enter the dimensions, weight, relevant zip codes, and freight class (if you know it) in the quote form.

2) You’ll see a list of qualified carriers for your shipment, their quote, and estimated transit time. Choose your carrier and book your shipment.

3) A FreightCenter expert will review your shipment and check for accuracy.

4) Once the shipment is scheduled, you’ll receive your bill of lading and other paperwork.

5) Double-check that all information is correct.

What if You Need Help?

FreightCenter is a leader in customer satisfaction because we support our technology with real, live shipping experts who help you. Need help booking your conveyor systems shipment? Questions about packaging? Have questions or concerns after you’ve booked your shipment? Our shipping experts are available to answer your questions. Save time, save money, and enjoy peace of mind. Get your free quote now or call us at (800) 716-7608.

To create value for our customers by delivering customized shipping solutions that meet their unique needs and to fulfill shipping demands from simple to complex with expertise, guidance and ingenuity.

Trust the experts at FreightCenter to give you the best prices and the most comprehensive options for all your LTL freight shipping needs.

We deliver optimized solutions for full or partial truckloads and competitive dry van, flatbed, and refrigerated freight pricing. We can cover your full truckload shipping needs.

Nationwide Expedited Trucking services move your freight securely and rapidly. Your freight requires fast delivery; our freight shipping experts can get your shipment fast, whether in one large box or a full truckload.

The most reliable Specialized Freight Services rates from all the top carriers are just a few steps away. From white glove service to international shipping, we've got you covered.

Frequently Asked Questions about Shipping Conveyor Systems

Q. What are conveyor systems?

Conveyor systems are mechanical apparatuses that automatically move materials and products throughout an area on a pre-laid track. You may see them at the grocery store when you check out your items or ride a conveyor staircase in a multi-story building.

Q. What's challenging about shipping conveyor belts?

Conveyor belts have many intricate parts that must be carefully packaged to avoid losing any of them during transport. They are also part of a large metal base, which can be difficult to ship due to their height and lack of sturdiness.

Q. What kind of shipping should I use for my conveyor system?

We recommend using less-than-truckload (LTL) shipping for your conveyor system. While all the parts make the system heavy, it is lighter in pieces. The parts are also sturdy enough to withstand being packed together with other shipments. As long as your conveyor system is packaged correctly, you won’t have to worry about it arriving at its destination in more pieces than it started as.

3 Advantages of Shipping Conveyor Systems with FreightCenter

25+ Years of Service

We have over 25 years of experience, as evidenced by our extensive network of professional carriers. Our knowledgeable team of shipping experts is ready to help you optimize your small business for the intricate world of logistics.

Customizable Shipping Options

Need a liftgate? No problem! Need to ship your products quickly? We've got you covered! Our FreightCenter agents can offer you tailored solutions for your specific shipping needs, no matter what kind of small business you are.

Friendly Customer Support

Our customer support team has the answers to many of your shipping questions and concerns. We’re here to help you through every step of the shipping process, from initial inquiries to post-shipment issues.