Defining Inbound Logistics

Inbound logistics is a pivotal component of supply chain management that encompasses the processes and activities involved in transporting, handling, and storing raw materials, components, and goods as they enter an organization’s premises. This integral facet of the supply chain focuses on efficiently managing the inflow of materials from suppliers or production sources to support the manufacturing or production processes.

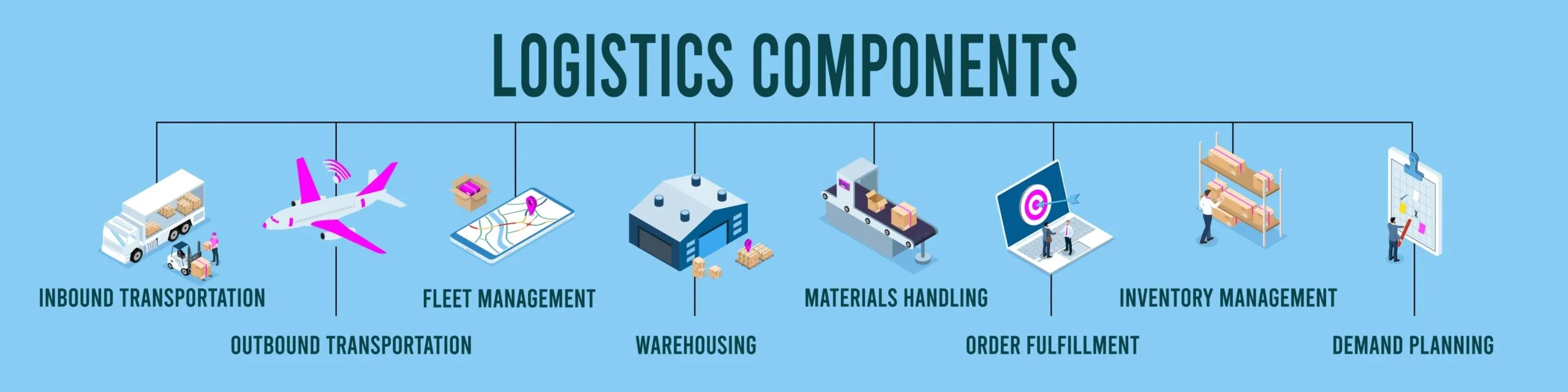

Key Elements of Inbound Logistics:

- Procurement: At the core of inbound logistics is the procurement process, involving the identification, selection, and sourcing of raw materials and components from suppliers. Establishing robust relationships with suppliers becomes imperative to ensure the timely and reliable delivery of materials in accordance with production schedules.

- Transportation: Inbound logistics incorporates the planning and execution of transportation strategies to bring materials from suppliers to the organization’s facilities. This includes choosing the most cost-effective and efficient modes of transportation, negotiating favorable freight terms, and optimizing transportation routes.

- Warehousing and Storage: Upon arrival, materials need to be efficiently stored and managed. Warehousing plays a crucial role in inbound logistics, encompassing activities such as inventory management, storage optimization, and ensuring that the right materials are available when needed for the production process.

- Order Processing and Receiving: The order processing and receiving stages involve the verification of delivered materials against purchase orders, ensuring the accuracy and quality of the received goods. This step is vital for maintaining the integrity of inventory records and preventing disruptions in the production cycle.

- Collaboration with Suppliers: Inbound logistics emphasizes the need for collaboration and communication with suppliers. Establishing clear channels for information exchange, sharing production forecasts, and coordinating delivery schedules are essential for maintaining a smooth and reliable flow of materials.

The Significance of Inbound Logistics:

- Cost Reduction: Inbound logistics directly impacts the overall cost structure of a supply chain. Efficient management of transportation, storage, and handling of incoming goods can lead to significant cost savings. Organizations can negotiate better freight rates, minimize transportation expenses, and optimize warehouse space utilization through effective inbound logistics.

- Inventory Management: Timely and accurate inbound logistics contribute to improved inventory management. By streamlining the arrival of raw materials and components, organizations can minimize excess inventory levels and reduce carrying costs. This, in turn, enhances cash flow and ensures that production processes are not disrupted due to shortages or overstock situations.

- Supplier Relationships: Inbound logistics is closely tied to supplier relationships. Effective communication and collaboration with suppliers are essential for accurate delivery schedules and order fulfillment. Building strong partnerships with suppliers can lead to better negotiation power, reliable deliveries, and mutual understanding of each other’s operational needs.

Strategies for Optimizing Inbound Logistics:

- Supply Chain Visibility: Implementing advanced technology and software solutions for real-time tracking and monitoring of shipments can provide greater visibility into the supply chain. This transparency enables organizations to proactively address issues, anticipate delays, and make informed decisions to improve overall efficiency.

- Collaborative Planning: Establishing collaborative planning processes with suppliers fosters better coordination and alignment of activities. Sharing demand forecasts, production schedules, and inventory data allows for synchronized planning, reducing the likelihood of disruptions and ensuring a steady flow of materials.

- Consolidation and Batch Ordering: Consolidating shipments and implementing batch ordering can lead to cost savings and improved efficiency. By combining multiple orders into one shipment, organizations can negotiate better freight rates and reduce transportation expenses. This strategy also minimizes the number of incoming shipments, simplifying the receiving and handling processes.

- Optimized Transportation Management: Implementing efficient transportation management systems (TMS) helps organizations optimize routes, choose the most cost-effective carriers, and minimize transit times. This not only reduces transportation costs but also enhances the reliability of inbound deliveries.

- Cross-Docking: Cross-docking is a strategy that involves unloading incoming goods from suppliers and directly loading them onto outbound trucks with minimal storage in between. This approach reduces the need for warehouse storage space, accelerates order fulfillment, and lowers handling costs.

Inbound and Outbound Logistics: Unraveling the Distinctions in the Logistics Industry

In the intricate web of supply chain management, inbound and outbound logistics represent two distinct yet interconnected facets. These terms encapsulate the movement of goods at different stages of the supply chain, each bearing unique characteristics.

Inbound Logistics: Inbound logistics primarily revolves around the inflow of materials, components, and goods into a company’s premises. It encompasses activities such as procurement, transportation, storage, and handling of raw materials sourced from suppliers. The focus here is on efficiently managing the supply side of the equation to meet production requirements. Timely and cost-effective delivery of materials is crucial for maintaining optimal inventory levels and ensuring a seamless production process.

Outbound Logistics: Conversely, outbound logistics pertains to the flow of finished products from the production site or warehouse to the end consumers. It involves activities such as order fulfillment, packaging, transportation, and distribution. The goal of outbound logistics is to deliver the final products to customers in a timely and cost-efficient manner. Customer satisfaction is a key driver in outbound logistics, emphasizing the importance of accurate order processing and reliable delivery to meet market demands.

Key Differences:

- Direction of Flow: The fundamental distinction lies in the direction of the goods’ movement. Inbound logistics is concerned with materials flowing into the organization, while outbound logistics focuses on the movement of finished products leaving the organization.

- Processes and Objectives: Inbound logistics is more attuned to procurement, supplier relationships, and inventory management, aiming to support the production process. On the other hand, outbound logistics is geared towards customer satisfaction, emphasizing order fulfillment, timely delivery, and distribution efficiency.

- Cost Structures: Inbound logistics often influences the cost of goods sold (COGS) and operational costs related to the procurement of raw materials. In contrast, outbound logistics contributes to the cost of sales, encompassing expenses incurred during the distribution and delivery of finished products to customers.

- Relationships with External Stakeholders: Inbound logistics builds and nurtures relationships with suppliers, focusing on collaboration for timely and reliable material deliveries. Outbound logistics, meanwhile, extends these relationships to customers, emphasizing customer service, order accuracy, and on-time delivery.

Understanding the nuanced differences between inbound and outbound logistics is essential for organizations seeking to optimize their entire supply chain. By honing strategies in both areas, businesses can achieve a harmonious balance, ensuring a smooth flow of materials and products from suppliers to end consumers.

Streamlining Inbound Logistics with 3PL FreightCenter

Managing inbound logistics can be a complex and time-consuming endeavor for businesses of all sizes. From coordinating with suppliers to optimizing transportation routes, ensuring efficient receiving and storage – it’s a lot to handle. This is where 3PL FreightCenter steps in, offering a comprehensive suite of solutions to streamline your inbound operations and boost your bottom line.

What is 3PL FreightCenter?

FreightCenter is a leading third-party logistics (3PL) provider specializing in helping businesses optimize their inbound logistics. They act as a one-stop shop, taking care of everything from shipment procurement and tracking to warehousing and inventory management.

Here’s how using 3PL FreightCenter can benefit your business:

1. Reduced Costs and Increased Efficiency:

-

Freight Procurement: FreightCenter leverages its vast network of carriers and extensive buying power to negotiate the best possible rates for your inbound shipments. This can lead to significant cost savings compared to managing transportation yourself.

-

Optimized Transportation: FreightCenter’s transportation management system (TMS) helps you plan and execute the most efficient routes for your shipments, considering factors like distance, carrier availability, and real-time traffic conditions. This can lead to reduced shipping times and lower fuel costs.

-

Streamlined Warehousing: FreightCenter offers a variety of warehousing and distribution solutions, including cross-docking, consolidation, and kitting. This can help you optimize your inventory levels, reduce storage costs, and improve picking and packing times.

2. Improved Visibility and Control:

- Real-time Tracking: FreightCenter’s platform provides real-time visibility into the location and status of your shipments. This allows you to track your inventory in transit, proactively address any issues, and improve your overall supply chain visibility.

- Proactive Communication: FreightCenter keeps you informed throughout the inbound process, sending you notifications about shipment milestones, potential delays, and any other relevant updates. This proactive communication helps you stay ahead of schedule and make informed decisions.

3. Scalability and Flexibility:

- Pay-as-you-go Model: FreightCenter’s services are available on a pay-as-you-go basis, so you only pay for the services you use. This eliminates the need for upfront investments in infrastructure and personnel, making it ideal for businesses of all sizes.

- Customized Solutions: FreightCenter understands that every business has unique inbound logistics needs. They work closely with you to develop customized solutions that meet your specific requirements and budget.

Overall, using 3PL FreightCenter can help businesses:

-

- Reduce inbound logistics costs

- Improve efficiency and visibility

- Gain greater control over their supply chain

- Increase scalability and flexibility

If you’re looking for ways to streamline your inbound logistics and gain a competitive edge, 3PL FreightCenter is a powerful partner to consider.

In addition to the benefits mentioned above, here are some other reasons why businesses choose 3PL FreightCenter:

-

- Experienced team: FreightCenter has a team of experienced logistics professionals who can help you navigate the complexities of inbound logistics.

- Technology-driven solutions: FreightCenter leverages cutting-edge technology to provide you with real-time visibility and control over your shipments.

- Strong carrier relationships: FreightCenter has strong relationships with major carriers, ensuring you get the best possible rates and service.

If you’re ready to take your inbound logistics to the next level, contact 3PL FreightCenter today for a free consultation.

Inbound logistics is a critical component of supply chain management that directly influences an organization’s cost structure, inventory management, and overall operational efficiency. By adopting strategic approaches such as supply chain visibility, collaborative planning, consolidation, and optimized transportation management, organizations can enhance their inbound logistics processes, ultimately contributing to a more resilient and agile supply chain. Continuous improvement and adaptation to evolving technologies will be key for organizations looking to master the complexities of inbound logistics in an ever-changing business landscape.