Transforming Warehousing: Smart Storage & Robotics

Embracing the Future of Warehousing with Robotics and Smart Storage Solutions! Revolutionizing operations to boost efficiency as cutting-edge technology transforms how one stores and manages inventory. Discover how innovation is reshaping the warehouse landscape today!

A robotic revolution is unfolding in the heart of modern commerce, where supply chains weave like lifelines, and efficiency is the currency of success. It’s a transformation reshaping warehousing’s core, infusing the foundation with unprecedented efficiency, precision, and untapped potential. Welcome to the future of warehousing—where robotics and intelligent storage solutions converge to propel businesses into uncharted realms of productivity and competitiveness, allowing smaller companies to compete with more giant corporations.

FreightCenter is indispensable to its partners by staying present on current trends and logistics within the industry, enabling businesses to fully capitalize on advanced warehousing technologies by ensuring seamless, efficient, and reliable transportation of goods, ultimately leading to improved customer satisfaction and competitive advantage.

We provide competitive freight shipping prices and an all-inclusive, easy-to-use shipping experience for our customers. Exceeding our customers’ expectations results in thousands of satisfied customer reviews and repeat business. We believe in the power of our customer relationships. Check out FreightCenter reviews from real customers, and learn what they have to say about their freight shipping experience!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

Why Choose FreightCenter

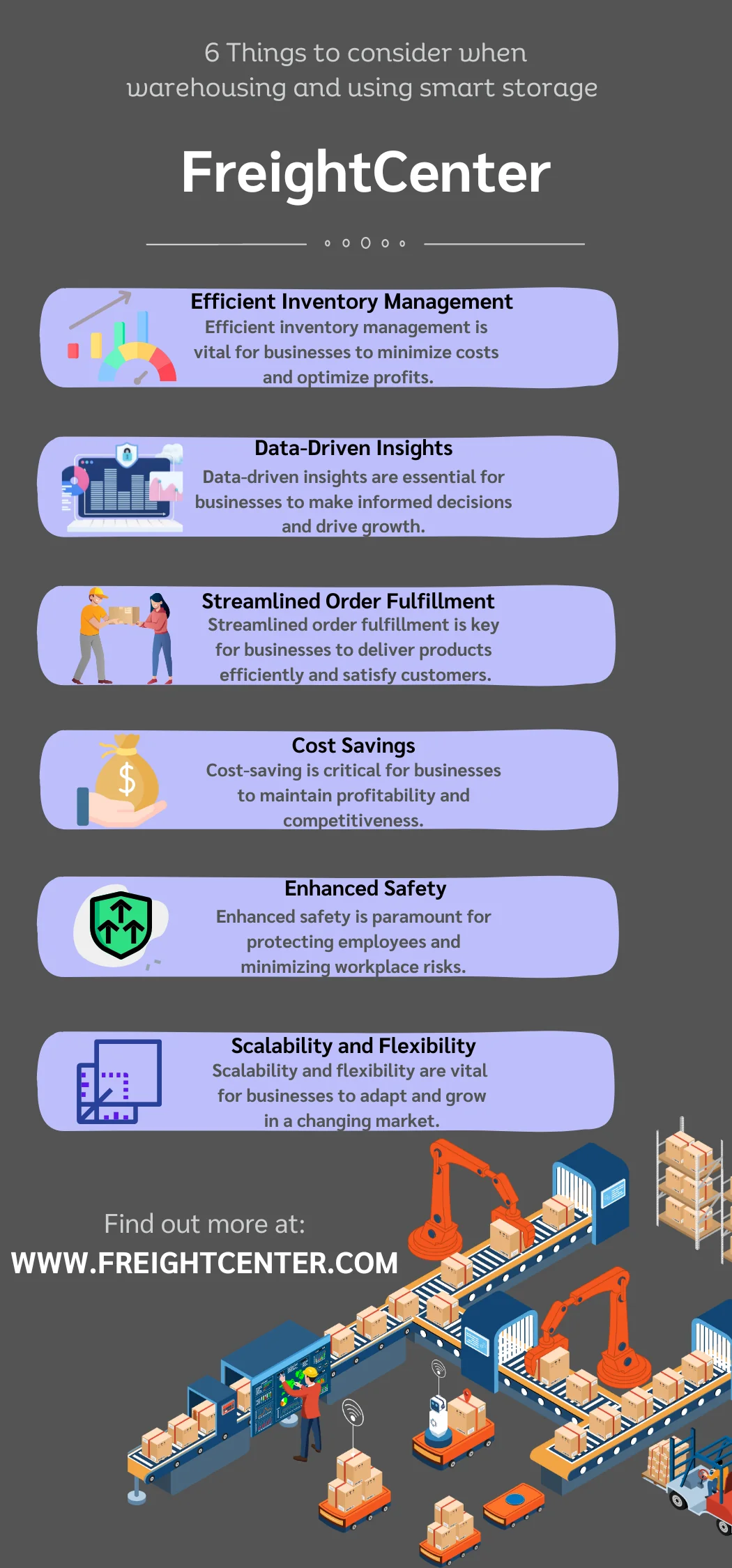

Using a shipping company like FreightCenter with revolutionizing warehousing through robotics and intelligent storage solutions can offer efficiency, cost savings, safety, and adaptability, ultimately helping companies and individuals better manage their supply chains and meet customer expectations in an ever-evolving market.

Efficient Inventory Management: Robotics and intelligent storage solutions can significantly enhance inventory management by automating picking, packing, and organizing tasks. When combined with a shipping company like FreightCenter, businesses can ensure timely and accurate shipments, reducing the risk of overstocking or stockouts, which leads to better customer satisfaction and cost savings.

Data-Driven Insights: Smart storage isn’t just about space optimization; it’s about harnessing data for more intelligent decision-making. Predictive analytics and AI algorithms empower warehouses to anticipate needs like never before. Advanced analytics and artificial intelligence algorithms sift through the data, uncovering patterns, anomalies, and opportunities that, in the past, were hidden in the labyrinth of shelves and pallets.

Streamlined Order Fulfillment: Intelligent storage systems integrated with robotics enable faster and more accurate order fulfillment. FreightCenter’s expertise in logistics and shipping can help companies optimize their shipping processes, ensuring that orders are efficiently picked, packed, and shipped, ultimately leading to shorter delivery times and happier customers.

Cost Savings: By utilizing robotics and intelligent storage, companies can reduce labor costs associated with manual warehousing tasks. FreightCenter can further enhance cost-efficiency by providing access to a network of carriers, helping businesses find the most cost-effective shipping options, and negotiating better freight rates.

Enhanced Safety: Robotics in warehousing can improve workplace safety by handling repetitive and potentially hazardous tasks. FreightCenter’s shipping expertise includes compliance with safety regulations and secure handling of goods, minimizing the risk of accidents and injuries during transportation.

Scalability and Flexibility: As businesses grow, their warehousing needs may change. Robotics and intelligent storage solutions offer scalability, allowing companies to adapt to fluctuating demand. FreightCenter’s services can scale alongside, offering flexible shipping solutions that accommodate changing inventory levels and shipping requirements without significant operational overhauls.

Incorporating these elements of efficient inventory management, driven by robotics and smart storage solutions, can revolutionize warehousing operations, making them more streamlined, cost-effective, and environmentally responsible.

Leveraging Robotics for Precise Inventory Control

In the context of revolutionizing warehousing with robotics and smart storage solutions, efficient inventory management becomes paramount. Warehouses are increasingly turning to robotics to automate inventory tracking and control. These exact machines utilize advanced sensors and scanning technologies to monitor stock levels in real time.

In part, they can swiftly identify discrepancies, ensuring that inventory counts remain accurate and reducing the risk of stockouts or overstock situations. With robotics, warehouses can maintain precise control over their inventory, optimizing order fulfillment processes and enhancing overall efficiency.

Maximizing Space Utilization with Smart Storage Solutions

Smart storage solutions and innovations are a game-changer for efficient inventory management in revolutionizing warehousing. By harnessing the power of data analytics and automation, these systems optimize storage space utilization. Dynamic slotting, for example, continually assesses demand patterns and adjusts the placement of products accordingly.

Automated retrieval systems, another facet of smart storage, make the most of vertical space, stacking goods efficiently. These solutions, driven by data-driven insights, ensure that each square foot of warehouse space is used optimally, reducing the need for additional storage facilities.

Real-time Monitoring and Smart Warehousing

In the era of revolutionizing warehousing, real-time monitoring is a critical component of efficient inventory management. IoT devices and intelligent warehousing technologies provide constant visibility into inventory levels, even within large and complex storage systems. This real-time data empowers warehouse managers to make informed decisions, such as reordering products when stock is low or redistributing inventory to reduce congestion. With the ability to access accurate, up-to-the-minute inventory information, warehouses can streamline operations and reduce carrying costs.

Automation Streamlines Replenishment Processes

Automation, driven by robotics and smart storage, has revolutionized warehouse replenishment processes within the context of revolutionizing warehousing. Robots can autonomously retrieve and restock products from storage systems when inventory levels drop below a certain threshold. Reducing the need for manual labor accelerates replenishment cycles, ensuring products are readily available to meet customer demand. Such automation improves efficiency and minimizes the risk of human errors associated with manual restocking.

Data-driven Demand Forecasting for Inventory Optimization

Efficient inventory management within the context of revolutionizing warehousing relies heavily on data analytics, particularly for demand forecasting. Smart storage solutions collect vast amounts of data, enabling warehouses to analyze historical sales patterns, seasonal trends, and customer behavior. With this data-driven insight, warehouses can accurately forecast demand and adjust inventory levels accordingly.

By maintaining optimal stock levels without overstocking or understocking, businesses can reduce carrying costs, increase inventory turnover, and ensure high customer satisfaction.

Sustainability and Efficient Inventory Management

Efficiency in inventory management within the context of revolutionizing warehousing extends beyond cost savings; it’s also about sustainability. Smart storage solutions contribute to sustainability by minimizing waste and reducing energy consumption. By optimizing space utilization, warehouses can operate in smaller, more energy-efficient facilities.

Additionally, the reduced need for excess packaging materials and the depreciation of obsolete inventory contribute to sustainability goals; in an age where environmental responsibility is paramount, efficient inventory management through robotics and smart storage aligns with economic and ecological objectives.

Data-driven insights into warehousing operations, driven by robotics and smart storage solutions, is the cornerstone of efficient, responsive, and sustainable warehousing in the modern era. These insights empower businesses to make proactive decisions, reduce costs, and enhance the overall customer experience, ensuring they stay at the forefront of the warehousing revolution

Data-Driven Insights Enhance Warehouse Efficiency

In revolutionizing warehousing with robotics and smart storage solutions, data-driven insights play a pivotal role. These insights are derived from integrating cutting-edge technologies like robotics and IoT devices. Businesses gain a profound understanding of their operations by collecting and analyzing data related to inventory levels, product movement, and warehouse operations.

Understanding the data, in turn, empowers them to make informed decisions, optimize processes, and enhance warehouse efficiency. Data-driven insights enable warehouses to adapt rapidly to changing demands, improving overall responsiveness.

Warehouse Innovation Relies on Logistics Technology

Logistics technology is at the core of leveraging data-driven insights to revolutionize warehousing. Robotics and smart storage solutions are being integrated with advanced tracking and monitoring systems. These technologies continuously capture real-time data about inventory levels, order fulfillment rates, and equipment performance.

This wealth of information provides the foundation for data-driven insights. By harnessing logistics technology, warehouses can ensure that products are efficiently stored, picked, and shipped, reducing lead times and enhancing the customer experience.

Robotics Integration for Real-time Data Collection

Warehouse robotics are instrumental in the collection of real-time data. Autonomous robots navigate the warehouse, scanning barcodes and RFID tags to track the location and movement of goods. They feed this data into centralized systems, creating a comprehensive picture of warehouse operations. With robotics integration, warehouses can monitor stock levels, identify potential bottlenecks, and make immediate adjustments to optimize inventory placement and retrieval.

Smart Warehousing and Inventory Optimization

Innovative warehousing, powered by data-driven insights, focuses on inventory optimization. Dynamic slotting, integral to intelligent storage solutions, continually analyzes demand patterns and product velocity. This analysis informs decisions about where to store products for maximum efficiency. Data-driven insights play a crucial role in these decisions, ensuring that frequently picked items are easily accessible while less often chosen items are stored optimally, reducing order fulfillment times and minimizing additional storage space.

Artificial Intelligence (AI) for Demand Forecasting

Artificial Intelligence (AI) is employed for demand forecasting within the context of revolutionizing warehousing. AI algorithms analyze historical data, considering seasonal trends, market fluctuations, and customer behavior. These algorithms generate accurate demand forecasts, guiding inventory management decisions. By leveraging AI-driven insights, warehouses can maintain optimal stock levels, reduce carrying costs, and avoid stockouts or overstock situations, ensuring a seamless and cost-effective supply chain.

Sustainability and Data-Driven Optimization

Sustainability goals are increasingly integrated into data-driven optimization efforts within revolutionizing warehousing. Innovative storage solutions, guided by data-driven insights, contribute to sustainability by optimizing space utilization, reducing energy consumption, and minimizing waste. These solutions ensure that warehouses operate efficiently in smaller, eco-friendly facilities. Additionally, data analytics help warehouses identify areas where further sustainability improvements can be made, aligning with economic and environmental objectives.

To create value for our customers by delivering customized shipping solutions that meet their unique needs and to fulfill shipping demands from simple to complex with expertise, guidance and ingenuity.

Truckload shipping, also known as full truckload (FTL), is a transportation option for freight that requires the entire trucks trailer space. Unlike LTL shipping, FTL shipping is reserved for larger commodities that exceed LTL weight and size limits, typically weighing more than 20,000 pounds or having dimensions that exceed 12 feet in length, 8 feet in width, and 8 feet in height. We deliver optimized solutions for full or partial truckloads and competitive dry van, flatbed, and refrigerated freight pricing. We can cover your full truckload shipping needs.

Specialized is a transportation option for items that require specialized handling, equipment, or shipping conditions. Specialized shipments may include high-value cargo, oversized cargo, or cargo that require temperature-controlled transportation. The most reliable Specialized Freight Services rates from all the top carriers are just a few steps away. From white glove service to international shipping, we've got you covered.

Transportation of temperature-sensitive goods such as perishable foods, pharmaceuticals, and chemicals in specialized refrigerated trailers or containers to maintain the required cold storage conditions throughout the journey, ensuring product integrity and safety. This a method crucial for industries reliant on preserving temperature-sensitive cargo during transit.

Rail freighting is a transportation method that utilizes trains to transport goods over long distances efficiently, cost-effectively, and with a lower carbon footprint than other modes of transport.

Comfortably With FreightCenter

FreightCenter stands at the forefront of a transformative era in the freighting industry, driven by smart storage, shipping, and warehousing practices innovations. With a strategic vision, FreightCenter is optimizing its operations, and the company recognizes that scalability and flexibility are essential components of this transformation.

Scalability

FreightCenter understands the importance of adaptability in a dynamic market. The ability to scale operations swiftly and efficiently is crucial in meeting customers’ evolving demands. By embracing scalable solutions, such as robotics and smart storage, FreightCenter is well-equipped to handle fluctuations in the market, expand its services, and cater to a broader spectrum of clients. This scalability ensures that FreightCenter remains agile and responsive in an ever-changing industry.

Flexibility

In the freighting business, flexibility is vital to success. FreightCenter’s commitment to flexibility is evident in its ability to tailor solutions to meet the unique needs of its customers. Whether accommodating diverse cargo types, offering temperature-controlled shipping options, or optimizing warehouse layouts, FreightCenter’s flexibility ensures it can adapt to clients’ specific requirements across various industries. This customer-centric approach enhances satisfaction and positions FreightCenter as a trusted partner in delivering reliable, customized freight solutions.

As FreightCenter advances into the future, it embraces innovation to enhance efficiency and maintain a scalable and flexible framework. This combination of strategic vision, cutting-edge technology, scalability, and flexibility places FreightCenter at the forefront of the freighting industry, ready to meet the challenges and opportunities while delivering exceptional service to its clients.

Smart Storage & Robotics FAQs

Q. What is smart storage in warehousing?

A. Smart storage refers to using advanced technologies and automation to optimize warehouse goods storage and retrieval. It often involves systems that use data-driven insights to decide where to store items for maximum efficiency.

Q. How do robotics enhance warehousing operations?

A. Robotics in warehousing involve using autonomous machines to perform various tasks such as picking, packing, and even inventory management. They improve efficiency, accuracy, and speed in warehouse operations.

Q. What are the benefits of smart storage solutions?

A. Smart storage solutions offer optimized space utilization, reduced labor costs, improved inventory management, faster order fulfillment, and increased efficiency.

Q. How can robotics be integrated into existing warehousing systems?

A. Integrating robotics into existing warehousing systems often involves a phased approach, including selecting suitable robotic systems, adapting workflows, and training staff. It’s essential to choose robots that can seamlessly work alongside human employees.

Q. Are smart storage and robotics suitable for all types of warehouses?

A. Smart storage and robotics can be adapted to various warehouse types, including e-commerce fulfillment centers, distribution centers, and cold storage facilities. However, the specific solutions and technologies may vary based on the warehouse’s needs and the type of goods being stored.

Q. What role does data play in smart storage and robotics?

A. Data is critical in smart storage and robotics. It’s used for real-time monitoring, demand forecasting, optimizing storage locations, and making decisions about robot movements. Data-driven insights are vital to maximizing the benefits of these technologies.

Q. How can businesses ensure the safety of workers when implementing robotics in warehousing?

A. Safety measures in robotics implementation include risk assessments, safety training for employees working alongside robots, and implementing safety features in robotic systems such as sensors and emergency stop buttons.

Q. Can smart storage and robotics help reduce environmental impact in warehousing?

A. Yes, smart storage and robotics can contribute to more sustainable and eco-friendly warehousing practices by optimizing space utilization, reducing energy consumption, and minimizing waste.

Q. What is the cost-effectiveness of implementing smart storage and robotics in warehousing?

A. While there are upfront costs associated with implementing these technologies, the long-term cost savings in reduced labor costs, improved efficiency, and optimized storage often make them a cost-effective investment.

Q. What industries benefit most from smart storage and robotics in warehousing?

A. Industries such as e-commerce, retail, pharmaceuticals, automotive, and food distribution benefit the most from adopting smart storage and robotics in warehousing due to their ability to handle high volumes and complex logistics.

Comfortably With FreightCenter

FreightCenter stands at the forefront of a transformative era in the freighting industry, driven by smart storage, shipping, and warehousing practices innovations. With a strategic vision, FreightCenter is optimizing its operations, and the company recognizes that scalability and flexibility are essential components of this transformation.

Scalability

FreightCenter understands the importance of adaptability in a dynamic market. The ability to scale operations swiftly and efficiently is crucial in meeting customers’ evolving demands. By embracing scalable solutions, such as robotics and smart storage, FreightCenter is well-equipped to handle fluctuations in the market, expand its services, and cater to a broader spectrum of clients. This scalability ensures that FreightCenter remains agile and responsive in an ever-changing industry.

Flexibility

In the freighting business, flexibility is vital to success. FreightCenter’s commitment to flexibility is evident in its ability to tailor solutions to meet the unique needs of its customers. Whether accommodating diverse cargo types, offering temperature-controlled shipping options, or optimizing warehouse layouts, FreightCenter’s flexibility ensures it can adapt to clients’ specific requirements across various industries. This customer-centric approach enhances satisfaction and positions FreightCenter as a trusted partner in delivering reliable, customized freight solutions.

As FreightCenter advances into the future, it embraces innovation to enhance efficiency and maintain a scalable and flexible framework. This combination of strategic vision, cutting-edge technology, scalability, and flexibility places FreightCenter at the forefront of the freighting industry, ready to meet the challenges and opportunities while delivering exceptional service to its clients.

Smart Storage & Robotics FAQs

Q. What is smart storage in warehousing?

Smart storage refers to using advanced technologies and automation to optimize warehouse goods storage and retrieval. It often involves systems that use data-driven insights to decide where to store items for maximum efficiency.

Q. How do robotics enhance warehousing operations?

Robotics in warehousing involve using autonomous machines to perform various tasks such as picking, packing, and even inventory management. They improve efficiency, accuracy, and speed in warehouse operations.

Q. What are the benefits of smart storage solutions?

Smart storage solutions offer optimized space utilization, reduced labor costs, improved inventory management, faster order fulfillment, and increased efficiency.

Q. How can robotics be integrated into existing warehousing systems?

Integrating robotics into existing warehousing systems often involves a phased approach, including selecting suitable robotic systems, adapting workflows, and training staff. It’s essential to choose robots that can seamlessly work alongside human employees.

Q. Are smart storage and robotics suitable for all types of warehouses?

Smart storage and robotics can be adapted to various warehouse types, including e-commerce fulfillment centers, distribution centers, and cold storage facilities. However, the specific solutions and technologies may vary based on the warehouse’s needs and the type of goods being stored.

Q. What role does data play in smart storage and robotics?

Data is critical in smart storage and robotics. It’s used for real-time monitoring, demand forecasting, optimizing storage locations, and making decisions about robot movements. Data-driven insights are vital to maximizing the benefits of these technologies.

Q. How can businesses ensure the safety of workers when implementing robotics in warehousing?

Safety measures in robotics implementation include risk assessments, safety training for employees working alongside robots, and implementing safety features in robotic systems such as sensors and emergency stop buttons.

Q. Can smart storage and robotics help reduce environmental impact in warehousing?

Yes, smart storage and robotics can contribute to more sustainable and eco-friendly warehousing practices by optimizing space utilization, reducing energy consumption, and minimizing waste.

Q. What is the cost-effectiveness of implementing smart storage and robotics in warehousing?

While there are upfront costs associated with implementing these technologies, the long-term cost savings in reduced labor costs, improved efficiency, and optimized storage often make them a cost-effective investment.

Q. What industries benefit most from smart storage and robotics in warehousing?

Industries such as e-commerce, retail, pharmaceuticals, automotive, and food distribution benefit the most from adopting smart storage and robotics in warehousing due to their ability to handle high volumes and complex logistics.