How to Ship Construction and Building Materials

Construct your dreams with our building materials shipping service! From sturdy lumber to sleek steel, we deliver the foundation for your projects. Explore our seamless shipping solutions and turn your vision into reality today!

Have you ever wondered how construction materials like bricks, wood, cement, and steel end up at building sites? Transporting construction and building materials is an essential part of the construction industry. When new buildings or projects are planned, these materials must be shipped from factories and suppliers to the construction site. Contractors rely on delivery services to ship their wood, and FreightCenter can do the job.

Building construction projects is exciting, but have you ever wondered how all those materials get to the construction site? Shipping construction materials is a crucial part of the construction process, ensuring that everything needed for the project arrives safely and on time. FreightCenter can help get your construction materials to their destination on time and efficiently. Here are seven things to remember when shipping building materials.

We provide competitive freight shipping prices and an all-inclusive, easy-to-use shipping experience for our customers. Exceeding our customers’ expectations results in thousands of satisfied customer reviews and repeat business. We believe in the power of our customer relationships. Check out FreightCenter reviews from real customers, and learn what they have to say about their freight shipping experience!

Awards and Endorsements

- 2021 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

Shipping Construction and Building Materials: A Guide for a Smooth Journey

1. Planning and Coordination

The first step in shipping construction materials is careful planning and coordination. Builders and contractors work closely with suppliers to determine the quantity and type of materials needed for the project. They also consider the delivery timeline, ensuring the materials arrive just before construction begins. This planning phase is essential to avoid delays and keep the construction project on track.

2. Proper Packaging and Labeling

Before shipping, all construction materials must be properly packaged to protect them during transit. Fragile items, like glass or tiles, require extra care with secure packaging to prevent breakage. Additionally, all packages should be labeled clearly with information like the contents, handling instructions, and destination address. Proper packaging and labeling help ensure that the materials arrive in good condition and are easily identified upon arrival.

3. Choosing the Right Transportation Mode

Shipping construction materials often involves using different transportation modes. Trucks may be used for shorter distances, while cargo ships or trains might be more suitable for longer distances or international shipping. The transportation mode choice depends on factors like the quantity of materials, distance, and cost-effectiveness. Builders and suppliers carefully select the best transportation mode to ensure timely and efficient delivery.

4. Loading and Securing the Materials

Once the materials are ready for shipping, they are loaded onto the chosen vehicles. This step requires careful planning to ensure that the materials fit securely and are evenly distributed to avoid any damage during transportation. Workers use equipment like forklifts or cranes to safely load heavy materials like steel beams or concrete blocks.

5. Freight Tracking

During shipping, keeping track of the package’s journey is essential. Many transportation companies offer freight tracking services, providing a tracking number that allows builders and contractors to monitor the shipment’s status in real-time. Freight tracking helps ensure the materials are on schedule and allows quick action in case of any unexpected delays.

6. Customs and Documentation (for International Shipping)

Materials must go through customs clearance for international shipping. This involves providing the necessary documentation, such as invoices and permits, to comply with import and export regulations. Working with experienced shipping partners can help you navigate these processes smoothly.

7. Unloading and Delivery

Upon arrival at the construction site, the materials are carefully unloaded from the vehicles. Workers use appropriate equipment and take safety precautions to handle the materials efficiently. Once unloaded, the materials are stored safely and organized, ready for use in the construction project.

1. Smooth Sailing: Planning and Coordinating Your Shipping

Have you ever wondered how those big and heavy building materials, like bricks, cement, and wood, get to a construction site? It’s all thanks to a clever process called construction logistic planning. Builders and suppliers carefully plan and coordinate the shipping of building materials, ensuring they arrive at the construction site in perfect condition and on time.

Understanding Your Construction Project Needs

The first step in planning is understanding what building materials your construction project requires. Builders and contractors work closely with architects and engineers to figure out the suitable types and amounts of materials needed. They also consider the size of the building, the design, and how long the construction will take.

Finding Reliable Suppliers

Once you know what materials you need, it’s time to find the right suppliers. Builders look for suppliers with a good reputation who can provide high-quality materials. They want someone who can deliver the materials on time and meet the project’s specific requirements.

Scheduling Your Deliveries

With the supplier chosen, you and the supplier work together to schedule the deliveries. You plan when and where the materials will be delivered, considering the construction timeline and the space you have at the construction site to store the materials.

2. The Importance of Proper Packaging and Labeling

When it comes to building and construction projects, the journey of construction materials from the supplier to the construction site is a critical part of the process. Proper packaging and labeling is one key aspect that ensures the safe and efficient delivery of these materials. Proper packaging and labeling are essential for shipping construction and building materials.

Protecting the Building Materials

Construction materials, such as bricks, tiles, glass, and steel, are often heavy and delicate. Proper packaging ensures that these materials are well-protected during transportation. Suppliers carefully pack the materials in sturdy containers, crates, or pallets to prevent damage or breakage. For example, glass and tiles are carefully wrapped or packed in materials like bubble wrap or foam to safeguard them from cracks or chips. By securing the materials with the right packaging, builders, and contractors can be confident that the materials will arrive at the construction site in excellent condition.

Avoiding Loss and Waste

In the construction industry, time and resources are valuable. Improperly packaged materials can lead to loss and waste. For instance, if a shipment of bricks arrives with several broken pieces due to inadequate packaging, those bricks may become unusable and need to be replaced. This not only causes delays but also results in unnecessary expenses. Proper packaging helps minimize such losses, ensuring every construction material arrives intact and ready for use.

Ensuring Easy Identification

Labeling is an essential part of proper packaging. Each package should be clearly labeled with important information, including the contents, quantity, and handling instructions. When construction materials arrive at the site, proper labeling helps workers quickly identify the needed materials. This saves time and effort, allowing construction work to proceed smoothly. For instance, workers can easily distinguish between different tiles or beams, making the construction process more efficient.

Safety First

Safety is a top priority in any construction project. Proper packaging and labeling contribute to the safety of everyone involved. Properly packed and labeled construction materials reduce the risk of accidents during transportation and unloading. Workers can confidently handle the materials, knowing they are secure and have clear instructions for handling.

Compliance with Regulations

Proper packaging and labeling also help ensure compliance with shipping regulations. Some materials may have specific packaging requirements for transportation, especially if they are hazardous or require special handling. Following these regulations is essential to avoid penalties and ensure the safety of the transportation process.

Eco-Friendly Packaging

In recent years, there has been a growing emphasis on eco-friendly practices in the construction industry. Using sustainable and recyclable packaging materials helps reduce the environmental impact of shipping. Builders and suppliers can explore options like biodegradable packaging materials to align with eco-friendly initiatives.

3. Choosing the Right Transportation Mode

Have you ever wondered how construction materials like bricks, wood, and steel get from the factory to the construction site? It’s all about choosing the right transportation mode. Selecting the best way to transport these materials is crucial for a successful construction project. Builders and suppliers choose the suitable transportation mode for shipping construction and building materials.

Understanding Transportation Options

Before making any decisions, builders and suppliers must know their transportation options. There are several ways to ship construction materials, each with benefits and limitations. Some standard transportation modes include trucks, trains, cargo ships, and even airplanes for international shipping.

Distance and Delivery Time

The distance between the supplier and the construction site is crucial in choosing the transportation mode. Trucks are often the best choice for shorter distances within a city or nearby areas. They can make quick deliveries and easily navigate through city streets. However, cargo ships or trains may be more suitable for longer distances, like shipping materials from one state to another or even to different countries. They can carry more significant quantities of materials and cover longer distances efficiently.

Quantity of Materials

The quantity of construction materials being shipped also impacts the choice of transportation mode. For small amounts of materials, trucks can handle the job well. They are flexible and can make multiple deliveries in one day. However, using cargo ships or trains can save time and money when dealing with large quantities. These transportation modes have more capacity to carry heavy loads in a single trip.

Cost-Effectiveness

Cost is an important consideration for any construction project. Builders and suppliers must weigh the expenses of different transportation modes. Trucks may be convenient for short distances, but they can be more expensive for long hauls. Cargo ships and trains, on the other hand, may have higher upfront costs, but their capacity to carry large loads makes them more cost-effective for longer distances.

Special Handling Requirements

Some construction materials may have special handling requirements. For example, delicate materials like glass or tiles need extra care during transportation. Trucks or cargo ships equipped with proper handling facilities may be preferred in such cases. Airplanes may also be used for delicate materials during international shipping, as they provide faster delivery while ensuring careful handling.

Environmental Impact

Builders and suppliers are increasingly mindful of the environmental impact of transportation. Some transportation modes, like cargo ships, have lower greenhouse gas emissions per unit of cargo than trucks. Greener transportation options can help reduce the project’s carbon footprint and promote sustainability.

The cost of shipping construction and building materials can vary based on various factors. Consider the following when estimating shipping costs:

Heavier and larger materials generally incur higher shipping costs due to increased handling and transportation requirements.

Longer shipping distances typically result in higher costs due to fuel consumption and transportation time.

Different shipping methods, such as ground, air, or ocean freight, have varying price structures. Expedited shipping options may offer faster delivery but at a higher cost.

Consider obtaining insurance coverage to protect valuable or fragile building and installation materials during transit.

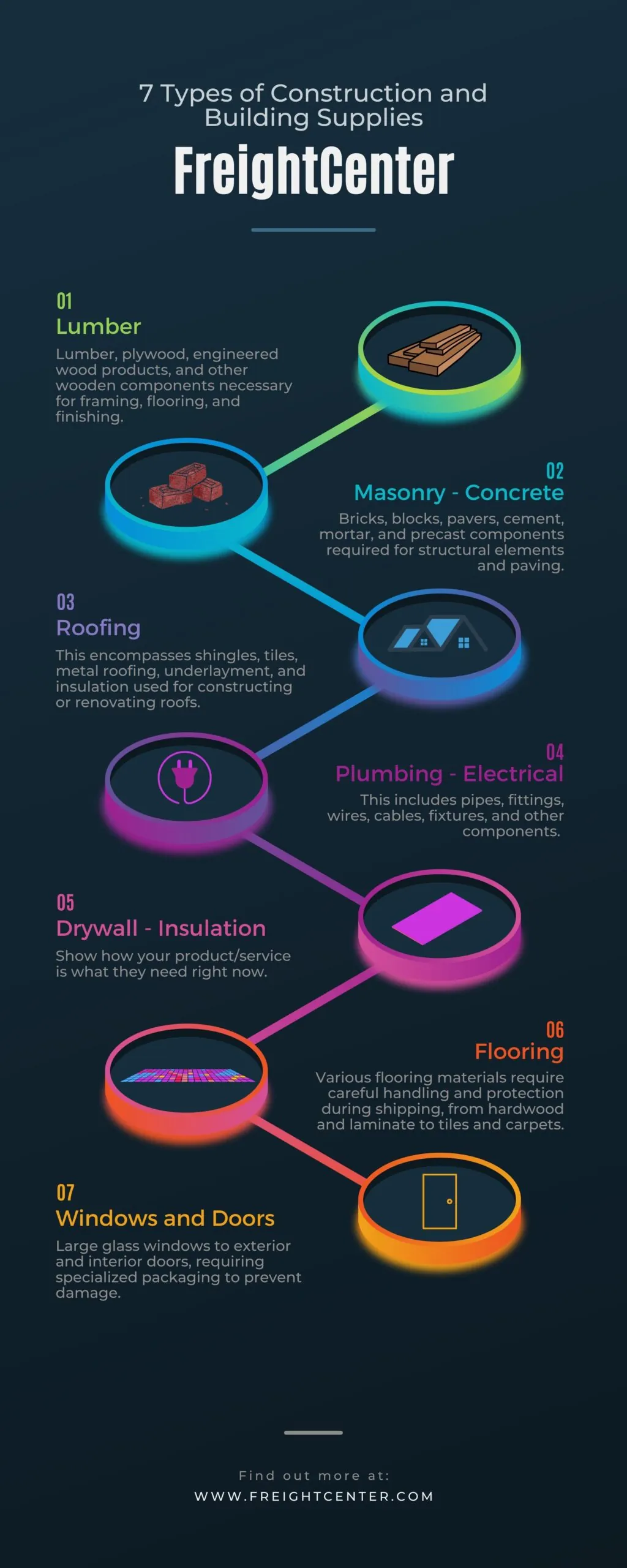

Types of Building Materials and Construction Supplies

Lumber and Wood Products

This category includes dimensional lumber, plywood, engineered wood products, and other wooden components necessary for framing, flooring, and finishing.

Masonry and Concrete Products

These materials include bricks, blocks, pavers, cement, mortar, and precast components required for structural elements and paving.

Roofing Materials

This encompasses shingles, tiles, metal roofing, underlayment, and insulation used for constructing or renovating roofs.

Plumbing and Electrical Supplies

This includes pipes, fittings, wires, cables, fixtures, and other components necessary for plumbing and electrical installations.

Drywall and Insulation

Drywall sheets, joint compounds, insulation batts, and spray foam are essential for interior walls and energy efficiency.

Flooring Materials

Various flooring materials require careful handling and protection during shipping, from hardwood and laminate to tiles and carpets.

Windows and Doors

These items range from large glass windows to exterior and interior doors, requiring specialized packaging to prevent damage.

6. Navigating Customs and Documentation for Shipping Construction and Building Materials

Shipping construction and building materials is like sending a special package to a faraway destination. But before these materials can reach their intended construction site, they must pass through customs and have the right documentation. Let’s explore what customs and documentation mean in shipping construction materials and why they are crucial for a successful journey.

What are Customs and Documentation?

Customs is a government agency responsible for controlling the flow of goods in and out of a country. When construction materials are shipped internationally, they must go through customs clearance. This means they are checked and approved by customs officials before they can enter a new country.

Documentation refers to the paperwork and records required for shipping materials across borders. It includes invoices, permits, certificates, and other essential documents that prove the materials’ origin, contents, and legal compliance.

Preparing the Documents

Before construction materials are shipped to another country, builders and suppliers must ensure they have all the necessary documentation. This includes preparing invoices that detail the materials’ value, packing lists that describe what’s inside each package, and certificates that confirm the materials meet safety standards.

Following Import Regulations

Different countries have their own rules and regulations for importing construction materials. Builders and suppliers must research and follow these regulations to avoid any issues at customs. Some materials may be restricted or require special permits, so knowing these requirements in advance is essential.

Submitting the Documentation

Once all the paperwork is ready, it must be submitted to customs before the materials arrive at the country’s borders. This allows customs officials to review and verify the documents, ensuring everything is for a smooth clearance process.

Inspections and Clearances

Customs may inspect the materials to ensure they match the information provided in the documentation. This step is done to prevent any illegal or unsafe materials from entering the country. If everything is in order, customs will issue the necessary clearances, allowing the materials to proceed to the construction site.

Paying Duties and Taxes

Sometimes, customs may require builders and suppliers to pay duties and taxes for importing construction materials. Duties are government fees. In contrast, taxes are charges based on the materials’ value. Paying these fees is an important part of the customs clearance process.

Working with Customs Broker

Navigating customs procedures can be complex, especially for international shipments. Builders and suppliers often work with customs brokers, experts in customs regulations and documentation. These brokers help ensure that all the required paperwork is prepared accurately and submitted on time.

7. Bringing Construction Materials to Life

Shipping construction and building materials is like sending a treasure hunt package to a construction site. Once the materials have traveled far and wide, it’s time for the exciting finale – unloading and delivery! In this article, here’s how builders and workers bring these essential materials to life at the construction site through efficient unloading and delivery.

Preparing for Arrival

Builders and workers prepare for the big day before the construction materials arrive at the site. They plan where the materials will be unloaded and stored. This preparation ensures a smooth process and helps prevent any delays or confusion.

Safety First

Safety is a top priority during unloading and delivery. Builders and workers wear appropriate safety gear, such as helmets and gloves, to protect themselves. They also ensure the unloading area is clear of obstacles and safe for moving materials around.

Unloading Heavy Materials

Some construction materials, like steel beams and concrete blocks, can be heavy. Builders use equipment like cranes, forklifts, and hoists to carefully unload these materials from the vehicles. Workers operate these machines with skill and precision to avoid any accidents.

Storing the Materials

Once the materials are unloaded, builders and workers store them organizationally. They group similar materials, making it easier to find what they need when starting the construction work. Proper storage prevents damage and ensures that materials are readily available when needed.

Checking the Inventory

Builders and workers carefully check the inventory of materials upon delivery. They compare the list of materials received to the shipping documents to ensure everything is accounted for. This step helps ensure all items are included.

Moving Materials to the Construction Area

After unloading, the materials are moved from the storage area to the construction site. Workers use wheelbarrows or carts to transport smaller materials like bricks or tiles. They may use specialized trolleys or equipment for heavier materials like steel beams.

Setting Up for Construction

Once the materials are at the construction site, builders and workers prepare to use them for the project. They position the materials in the right spots and assemble them according to the construction plans. It’s like putting together a giant puzzle!

Keeping the Site Clean

Builders and workers keep the construction site tidy throughout the unloading and delivery process. They remove any packaging materials and debris, ensuring a safe and clean environment for everyone working on the project.

Recycling and Reusing

In some cases, construction materials can be recycled or reused. Builders collect any excess or unused materials and store them for future projects. Recycling and reusing materials help reduce waste and protect the environment.

Shipping construction and building materials are well-planned and coordinated. It involves proper packaging, labeling, choosing the correct transportation mode, loading and securing the materials, freight tracking, customs clearance (for international shipping), and safe unloading at the construction site. By following these steps, builders and contractors ensure that all the materials needed for their construction projects arrive safely and on time, paving the way for a successful and smooth construction journey.

Why Choose FreightCenter?

Construction crews can build only as quickly as they receive materials. It makes sense for logistics professionals to help manage the supply chain for new residential projects. An experienced third-party logistics company like FreightCenter can work with general contractors and subcontractors to ensure that the process of shipping construction materials is shipped in a way that makes sense – efficiently and economically. FreightCenter is here to help you navigate the shipping process so that you can get your package to its destination on time.

Shipping Options

FreightCenter offers various shipping options, including less-than-truckload (LTL) and full-truckload (FTL) services. These options allow you to choose the most cost-effective and efficient method for transporting your building materials.

Carrier Network

FreightCenter has established relationships with a vast network of carriers. We can leverage these connections to find the best carriers for transporting specific building materials to your desired locations.

Pricing and Negotiation

FreightCenter has the expertise to negotiate favorable shipping rates due to the volume of shipments they handle. We can provide competitive pricing and ensure you get the best value for your shipping needs.

Freight Tracking

Tracking shipments is crucial in the shipping process. FreightCenter provides tracking services, enabling you to monitor the status and location of your building materials during transit.

Documentation and Compliance

Shipping building materials may involve various regulations and paperwork. FreightCenter can assist in handling the necessary documentation, ensure compliance with shipping regulations, and avoid potential delays or issues.

Insurance and Claims

FreightCenter offers cargo insurance options to protect your building materials against loss or damage during transit. If any issues arise, we can assist in filing claims and resolving disputes with the carrier.

Expert Assistance

FreightCenter has experienced logistics professionals who can provide guidance and support throughout the shipping process. We can help you plan the most efficient routes and address any potential challenges that may arise.

Shipping Construction and Building Materials FAQs

Q. How are materials transported on a construction site?

Materials on a construction site are typically transported using trucks or heavy machinery. The process involves loading the materials onto the truck or trailer, which is then transported to the job site. This method ensures efficient and timely delivery of building materials.

Q. How do construction companies transport materials?

Construction companies transport materials using semi trucks and flatbed trailers designed to handle large construction materials. These vehicles are ideal for accommodating the size and weight of construction freight. Additionally, shippers must secure resources at different building sites to ensure materials are delivered efficiently.

Q. What is logistics of construction materials?

Construction logistics involves planning, coordinating, and managing the timely and cost-effective delivery of construction materials, equipment, and labor to a construction site. It ensures the smooth flow of resources to support the construction process. Efficient logistics for construction materials is crucial to avoid delays and minimize costs in a construction project.

Q. What are some common types of construction materials?

Common types of construction materials include concrete, steel, wood, stone, and brick/masonry. These materials are widely used in construction projects due to their durability, strength, and versatility. With their unique properties, they provide the necessary structural support and aesthetic appeal for various building needs.

Q. What are the common material used in building?

The common materials used in building construction include wood, cement, aggregates, metals, bricks, concrete, and clay. These materials are chosen based on their cost-effectiveness for building projects.

Q. What are 5 building materials?

The five commonly used building materials in construction are steel, concrete, wood, stone, and brick/masonry. Steel provides strength and fracture resistance, while concrete offers durability. Wood is a versatile option, and stone and brick/masonry add aesthetic appeal. These materials are essential for creating durable and aesthetically pleasing structures in construction projects.

Q. What are the four most common structural materials?

The four most common structural materials are masonry, timber, steel, and reinforced concrete. Each material has its unique properties and influences the geometry of structures differently. We will now discuss the influence of material properties on structural geometry in relation to these four principal materials.

Q. What is the most common building material in North America?

The most common building material in North America is wood, which is widely used in construction to frame homes. However, with the emergence of modern materials and construction methods, wood’s disadvantages are becoming more apparent.