Shipping Manufacturing Equipment

Shipping Manufacturing Equipment with Confidence

From precision tools to heavy machinery, we make shipping manufacturing equipment secure, affordable, and stress-free, no matter the size or destination.

More about Shipping for the Manufacturing Industry:

Logistics for Manufacturing Companies Shipping Machinery and Equipment Crating Heavy Machinery Shipping CNC MachinesFreight Shipping for Manufacturing Equipment Made Simple

Moving manufacturing equipment can be a complex process. These machines are large, heavy, and often designed to perform a single task, so relocating them from one place to another requires careful planning, the right equipment, and expertise.

If you’re in the business of making things, you already know how critical your equipment is. Whether you’re shipping a single CNC machine or relocating an entire production line, you can’t afford delays or damage. We understand that, having worked with thousands of manufacturers who depend on their machinery every day.

Some machines arrive crated. Others don’t. Some require a flatbed, while others can be accommodated in an LTL shipment. There’s no one-size-fits-all solution, which is why we look at each job individually.

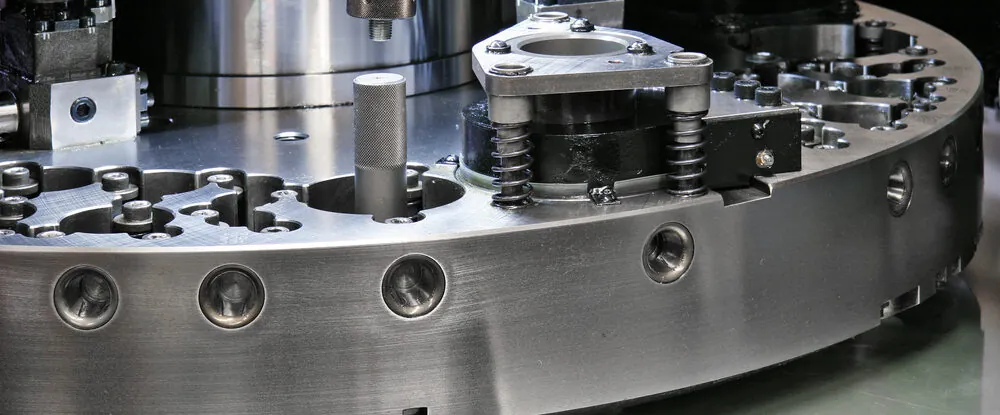

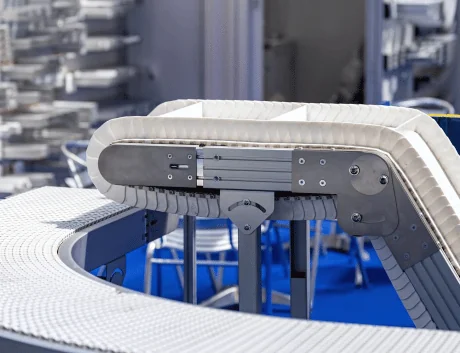

We’ve helped ship CNC machines, lathes, hydraulic presses, injection molding machines, conveyors, and more. Some are moving across the state. Others are going overseas. No matter the size or destination, we’ll help you figure out the best way to get it there.

Thousands of businesses trust FreightCenter to move their freight faster, smarter, and cheaper! From unbeatable rates to top-notch service, our customers are raving about their shipping success.

See why they keep coming back!

Award-Winning Service, Trusted by Shippers Everywhere!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

Why Choose FreightCenter

We understand that shipping manufacturing equipment isn’t just about getting something from point A to point B. It’s about protecting your investment, minimizing downtime, and ensuring everything arrives intact and on time.

We’ve been helping manufacturers with freight shipping for over two decades. That means we’ve seen it all: oversized machinery, tight pickup windows, loading docks that don’t line up, last-minute changes, and all the unexpected curveballs that come with moving heavy equipment.

You don’t need to be a logistics expert to get this right. That’s our job.

We work with a vast network of carriers across the country, enabling us to help you find the best option for your specific equipment, budget, and timeline. And we don’t disappear after you book—we’re here to help track your shipment, answer questions, and solve problems if they come up.

This isn’t a one-size-fits-all service. We treat every shipment like it matters—because it does.

3 Easy Steps to Ship Manufacturing Equipment

Step-by-step guide with icons:

- Get a Quote – Use our online tool or call for tailored pricing

- Book Your Shipment – Choose the carrier and transit time that fits your needs

- Track and Manage – Stay informed with updates and expert support

Pro Tip Box:

For high-value machinery, ask about FreightCenter’s cargo insurance options.

What Counts as Manufacturing Equipment?

The first step to shipping manufacturing equipment is to understand what exactly qualifies as “manufacturing equipment”. Simply put, it refers to tools, machinery, and systems used in industrial production. Common examples include the following:

- CNC machines

- Injection molders

- 3D printers

- Milling machines

- Lathes and presses

- Packaging and labeling machines

- Assembly line systems

- Robotic arms and automation systems

If it is used to produce, shape, move, or assemble products, it is likely classified as manufacturing equipment. Understanding what constitutes manufacturing equipment is essential for packaging and shipping it properly.

How to Ship Manufacturing Equipment

Shipping manufacturing equipment can be challenging due to its size, weight, and shape. Proper planning, precision, and the right logistics partner are essential to ensure safe delivery. Here’s a step-by-step breakdown of how to ship manufacturing equipment:

1. Assess the Equipment

First, review your equipment to determine its size and current condition. You will need to measure the dimensions (L x W x H) and weight of your equipment in preparation for your booking. Additionally, note any detachable parts that require separate packaging and fragile components that require specialized care during transport.

2. Choose the Right Packaging

You need to choose the proper packaging for your equipment. What you use will depend on the shape, weight, and durability of your machinery. Crating is great for small-to-medium-sized equipment due to its protection and stackability. Use moisture barriers and shock-absorbent materials inside the crate. Larger equipment should be wrapped and strapped onto a flatbed if disassembly isn’t possible. Make sure all parts are clearly labeled, and include specialized labels like “Do Not Stack” or “Fragile.”

3. Select the Appropriate Transportation Mode

After packaging your equipment, you can choose your shipping method based on freight size, durability, price, and necessary protection. For sturdy equipment on a budget, opt for LTL shipping. For larger freight needing extra protection, consider FTL or flatbed shipping. Review your options carefully to select the best choice for your equipment.

4. Schedule Pickup and Delivery

When booking your shipment, be sure to schedule both pickup and delivery appointments. In addition, you will need to select any additional services required for your pickup or delivery. These services include liftgate assistance, inside delivery and pickup, and limited access services, which are helpful for unusual pickup or delivery locations. Please note that if you miss an appointment, you can reschedule it, but a rescheduling fee will apply.

5. Track Your Shipment

As your shipment makes its journey to its final destination, you can keep track of it using advanced tracking systems. Your chosen carrier will provide their tracking information. If you booked through a third-party broker (like FreightCenter), then you can use their tracking tools. You will need a tracking or booking number to access the software.

Choosing the right shipping method is essential for protecting your manufacturing equipment and keeping your business on schedule. The best method depends on the type, size, weight, and urgency of your shipment. At FreightCenter, we help you select the right option based on your needs, budget, and delivery timeline.

Ship CNC machines safely with FreightCenter. Get expert help, competitive freight quotes, and secure transport for mills, routers, and turning centers.

FreightCenter makes shipping injection molding machines simple. Compare carrier rates, schedule pickups, and track your shipment with expert support.

Need to ship metal fabrication equipment? FreightCenter provides reliable freight solutions for lathes, shears, welders, and custom fab machines.

Move heavy hydraulic presses with ease. FreightCenter helps you compare rates, arrange flatbed or LTL freight, and ship safely with real-time tracking.

FreightCenter simplifies shipping assembly line machinery. Whether you're moving part of a line or the whole system, get reliable help and real-time quotes.

Shipping industrial 3D printers? FreightCenter offers secure, affordable options with expert guidance for large or delicate equipment.

FreightCenter ships conveyors and robotic arms with care. Book secure transport with top carriers and get expert help every step of the way.

Ship custom machinery with confidence. FreightCenter helps manufacturers move unique equipment safely with tailored freight solutions and expert guidance.

FreightCenter Services That Help You Ship Manufacturing Equipment

Shipping manufacturing equipment requires more than just a truck—it takes the right services, tools, and knowledge to move complex machinery safely and on time. That’s why FreightCenter offers a wide range of value-added services designed specifically to support manufacturers at every stage of the shipping process.

- Freight Class Assistance to Avoid Billing Surprises: Manufacturing equipment often falls into higher freight classes due to its size, shape, or density. Our experts help you determine the correct freight class, ensuring your shipment is accurately rated and avoiding unexpected charges and delays.

- Crating & Packaging Guidance to Protect your Investment: From crating large machinery to securing sensitive parts, proper packaging is crucial. We provide tips, material recommendations, and vendor connections to ensure your equipment is fully protected during transit.

- Inside Delivery and Liftgate Options for Facilities without Docks: Many manufacturing locations lack loading docks or forklifts. FreightCenter can arrange for liftgate service and inside delivery, ensuring your equipment is safely off the truck and into place; no heavy lifting required.

- Tracking and Notifications to Stay Informed: Stay updated with real-time shipment tracking and alerts. Know exactly where your equipment is, when it will arrive, and be prepared for unloading without surprises.

- Logistics Consulting for Complex or Recurring Shipments: If you’re coordinating multiple machines, managing recurring orders, or facing unusual logistics challenges, our consulting services can help create a streamlined strategy that saves time and cost.

Have questions or ready to ship? Call us at (800) 716-7608 to speak with a FreightCenter agent or try our free online quoting tool to get started today. Whether you’re shipping one machine or an entire facility, we’re here to help you do it right.

Frequently Asked Questions about Shipping Manufacturing Equipment

Q. What qualifies as manufacturing equipment for freight shipping?

Manufacturing equipment encompasses machines and tools used in industrial production, such as CNC machines, 3D printers, injection molders, and robotic arms. If it plays a role in assembling, shaping, or producing products in a factory setting, it qualifies as manufacturing equipment.

Q. How do I prepare manufacturing equipment for shipping?

Start by cleaning the equipment and removing any detachable or fragile parts. Crate or palletize it securely with proper labeling and moisture-resistant materials. FreightCenter provides guidance on packaging best practices and can recommend vendors for professional crating.

Q. Can FreightCenter help with packing materials?

Q. Do I need a liftgate for pickup or delivery?

If your facility lacks a loading dock or forklift, a liftgate is essential for safely loading and unloading heavy machinery. FreightCenter can arrange liftgate service as part of your shipment booking.

Q. What are the most common mistakes in shipping manufacturing equipment?

Shippers often overlook accurate weight and dimensions, forget to secure loose components, or fail to purchase freight insurance. FreightCenter helps prevent these issues with expert support from quote to delivery.

Q. Is freight insurance available?

Yes. We strongly recommend insuring high-value manufacturing equipment. FreightCenter offers optional third-party freight insurance during the booking process to protect your shipment against loss, damage, or other perils.

Q. Can I ship internationally?

Yes. FreightCenter offers international freight services, including customs documentation assistance and help selecting the right carrier for global transport.

Q. What if I need to ship multiple machines at once?

Shipping multiple machines can be coordinated as a single full truckload or split into multiple shipments, depending on your specific needs. FreightCenter will help optimize the route and freight type to ensure cost efficiency.

Q. What if my equipment is extremely heavy or oversized?

Oversized or overweight equipment may require heavy-haul transportation, flatbed shipping, or specialized transportation. FreightCenter works with carriers that specialize in handling large freight, ensuring your shipment remains compliant with weight and dimensional regulations.

Q. Do you offer white glove or inside setup services?

Yes, in select areas. White glove services include unloading, unpacking, and even light assembly. Contact FreightCenter to check availability and pricing for premium delivery options.

Q. How fast can my shipment be delivered?

Standard transit times range from 2 to 6 business days, depending on the distance and carrier availability. Expedited freight options are available for urgent shipments, but these may incur additional costs.

Q. Will I be notified when my equipment arrives?

Yes. FreightCenter provides tracking updates and delivery notifications, so you always know the status of your shipment. Our tracking tools are designed to keep you informed every step of the way.

Q. What type of carrier will transport my shipment?

Depending on the shipment size and needs, FreightCenter will match you with vetted carriers experienced in transporting industrial and manufacturing equipment.

Q. Why should I use FreightCenter instead of booking directly with a carrier?

FreightCenter offers access to multiple top-rated carriers, better rates through our volume discounts, and expert support throughout the process. You get more flexibility, transparency, and service without the hassle of managing it all on your own.

Q. How do I get a quote from FreightCenter?

You can use our free online quoting tool to compare rates from top carriers, or speak with one of our logistics experts at (800) 716-7608 for personalized support and guidance.

Planning for Downtime & Production Continuity

Avoiding Costly Delays

Strategic shipment timing and freight mode selection can keep your production line moving with minimal disruption. FreightCenter can find areas to cut costs in your post-production process, ensuring your bottom line is protected.

Coordinating Installation Schedules

Sync your delivery window with facility readiness. FreightCenter helps align freight transportation with crane, rigging, or install team availability, so your production schedule remains intact..

Backup & Redundancy Planning

Ship replacements or backup units proactively, or keep them in storage to be ready in case of an emergency customer order. FreightCenter works with you to prioritize urgent equipment when operations can’t pause.