Crafting Services & Shipment Preparation

Protect Your Freight with Custom Crating Solutions

Ensure your valuable shipments are safe and secure with FreightCenter's expert crating services. From fragile items to oversized equipment, our custom crating solutions are designed to safeguard your freight during transit. Start your stress-free shipping journey today!

Explore Helpful Resources for Crating and Shipping

Freight Class Calculator Compare Freight Carriers Freight Insurance OptionsThousands of businesses trust FreightCenter to move their freight faster, smarter, and cheaper! From unbeatable rates to top-notch service, our customers are raving about their shipping success.

See why they keep coming back!

Award-Winning Service, Trusted by Shippers Everywhere!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

Why Choose FreightCenter for Crate Shipping?

Expertise in Freight Shipping: With over 25 years in the logistics industry, FreightCenter is dedicated to guiding you through the entire logistics process, from beginning to end. Our goal is to make freight shipping easy to understand and book. Don’t waste time researching and receiving quotes from individual carriers- FreightCenter’s got your back!

Competitive Rates with Tailored Solutions: We prioritize high-quality customer service without breaking your wallet. We utilize our relationships with regional and national carriers to offer you competitive, affordable rates while providing personalized solutions to your needs. Need a liftgate? We got you! Want to expedite your order? Leave it to us! We’re ready to provide tailored solutions that don’t compromise your freight shipment.

Personalized Customer Support: FreightCenter is committed to satisfying our customers. Our friendly customer support team is here to help you every step of the way, from initial inquiries to post-shipment concerns. We handle all aspects of logistics, including tracking, paperwork, and communication with carriers, so you can focus on your business while we manage your shipment. Choose us for our reliable service and affordable quotes!

Crate Services & Shipment Preparation

Crating is considered the best way to protect many types of freight. Some shippers prefer to make their crates instead of having them made professionally. Customers shipping extremely fragile items with a high value, such as furniture, tend to have their containers made by a professional crating service. It can be very economical to pay to have your items crated by a company rather than buying all the supplies yourself and taking a day to build the crate.

Proper packing or crating will allow your shipment to withstand road vibrations and cross-docking during transit. If your item is fragile or has a high value, crating is the absolute best solution. Not only does crating provide the highest protection against damage and loss, but you also get the highest level of security to the strength of the crate. Strong build crates protect against damage and can stack items on top without damaging the contents inside. Crating can save money and possibly give a “stackable shipment” discount.

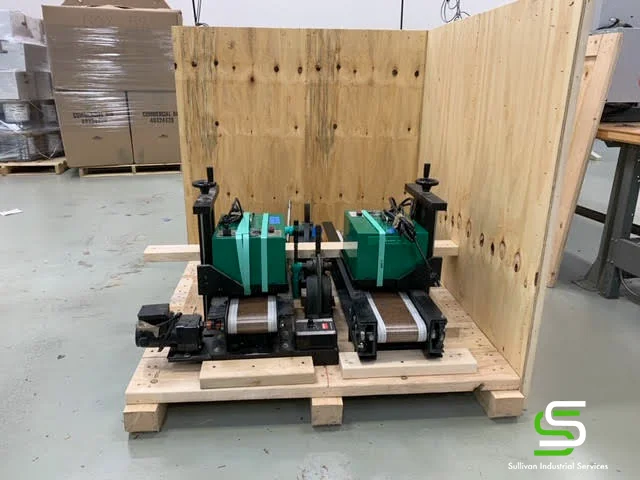

Trust a professional crating service like Sullivan Industrial Services

The short answer is yes! Please make sure you strap your crate to a pallet. Having your item palletized will allow you to move quickly by a forklift. Putting your container on a pallet may ensure your shipment gets on time. If your crate is on a pallet, the freight carrier can move it from one trailer to another.

It’s nearly a universal truth that packaging your freight on a shipping pallet helps keep it safer and more secure during transit and handling. Tips for palletizing your freight:

- Keep it contained.

If freight hangs over the edge of the pallet, damage may occur because there is no support for the freight while in transit.

- Flat tops rock.

Be sure the top of the pallet has a flat surface. Otherwise, place single containers of freight on an outside corner, or ship them separately.

- No love for interlocking.

The pallet loses its strength by arranging your freight in an interlocked pattern. Arrange boxes in a uniform and lined-up fashion for maximum strength.

- Birds of a feather flock together.

Different-sized boxes might not be uniform enough to achieve unit strength—Palletize boxes of similar shape together and ship other boxes separately or on their pallet.

- Flaps up before takeoff.

All box flaps and corrugations should be facing up, as they are the most compromised side of the box.

- Cuddle your cargo.

Wrap your shipment with blankets or other cushioned material to provide an extra layer of protection and buffering.

- No wiggle room

You can secure freight to the pallet with banding, shrink-wrap, or spray adhesive.

As an added level of protection, some shippers choose to shrink-wrap by strapping them to a pallet and shrink-wrapping it. This step is only sometimes necessary; however, shrink-wrapping your crate allows you to secure documentation and small accessories to the container.

Does A Crate Cost More To Ship?

The extra weight of the crate and its size will affect your final shipping price. It is common for a wooden crate and pallet to ad 100lbs+ to a shipment. It is essential to make sure your BOL shows the packed and palleted weight and dimensions on it. Please include the crate and pallet weight or measurements to ensure your shipment gets on time. Building your crate is something you can do. If not, we recommend that a professional crating company crate your shipment. Check out our packaging and crating tips below.

What Questions Should You Ask a Crating Service for hire?

- What quality packaging materials do they use?

- Do they custom measure and build to your specific needs?

- Do they offer any kind of warranty or insurance?

- Can they build the crate on site or does it need to be shipped to you?What are the estimated costs involved?

- Is the crate rated for domestic or international shipping?

- What weight and dimensions is the crate going to add to my shipment costs?

Freight Packaging

Learn the best ways to save time and money when you package and ship freight.

Packing Guide to Prevent Freight Damage

Avoid costly damage to your shipment by protecting it against road and warehouse conditions. This guide will help you prevent damage and loss by properly packing, securing, and labeling your shipment.

Unless your freight requires a full truckload, your shipment will be grouped with other less-than-truckload (LTL) shipments and shipped by truck. An adequately packed shipment is your best protection against damage. An improperly packed or poorly addressed load may cause delays and unnecessary damage.

We recommend following advice on how to pack and crate to avoid these problems.

What Is a Handling Unit?

A handling unit is a bundle of freight that is individually identified and transported. What may have started as ten individually packaged boxes, might now be ten boxes shrink wrapped together onto one pallet. If you have ten individual boxes that are all going to the same location, it makes sense to bundle them onto a pallet and ship as one handling unit. Not only does this method save you money by only shipping once, it’ll also save you the stress of having to keep track of ten individual shipments.

Types Packaging Your Freight Shipment

In the freight industry, we’re all about making things faster, more innovative, and overall more efficient. If there’s a way for a shipment to be condensed or for a truckload capacity to be maximized to save you money and time – we’re all over that. Luckily, there are countless methods for making shipping more seamless, the first way being – packaging. The way freight is packaged can make all the difference. It can change the shipping price, how it’s handled during transit, and even where it gets placed on a freight truck. Packaging your freight is a crucial step, not one on which you should cut corners. Various packaging options are available, and specific packaging options are best suited to the commodity you’re shipping.

Palletizing

A shipping pallet is an option when you have an oversized item that won’t fit within the confinements of a crate. Additionally, shipping pallets are a wise choice when you have several smaller boxes to consolidate and shrink-wrap into one handling unit. Pro tip: Thoroughly bubble wrap your freight before shrink-wrapping it to the pallet. Pallets or skids come in standard sizes (48″ x 40″) that can easily be purchased, or ask your local grocer or large retailers if they can provide you with one. Large items and multiple boxes should be adequately palletized. Make sure your boxes or crates do not overhang the pallet. When boxes or containers are stacked on a pallet, the boxes should be distributed evenly. Use heavy-duty plastic wrap to strap or secure your item(s) directly to the pallet if needed.

Be sure you have a loading dock or forklift at the pick-up and delivery location. If the pick-up and delivery locations do not have a dock, you must request a truck with a lift gate. There is an additional charge for added equipment options.

To create value for our customers by delivering customized shipping solutions that meet their unique needs and to fulfill shipping demands from simple to complex with expertise, guidance and ingenuity.

Less than truckload (LTL) shipping is a smart logistics solution for businesses with smaller shipments. It combines multiple smaller shipments into a single truckload, optimizing space and reducing costs. LTL shipping offers affordability and efficiency while ensuring timely delivery, making it an ideal choice for companies looking to save on transportation expenses without compromising on service quality.

Rail shipping is a cost-effective and environmentally friendly transportation method that utilizes trains to move goods over long distances. It's known for its efficiency in handling large volumes of cargo, making it a sustainable and economical choice for businesses seeking reliable freight transport options.

Expedited shipping is a premium service designed to meet urgent delivery needs. It prioritizes speed and quick turnaround, ensuring that packages or goods reach their destination faster than standard shipping options. Expedited shipping is the go-to choice when time-sensitive deliveries are essential, providing businesses and individuals with reliable and prompt service for critical shipments.

White glove shipping is a premium service that goes beyond standard delivery, offering meticulous handling, specialized packaging, and in-home setup or installation for valuable or delicate items, ensuring a seamless and hassle-free experience for customers.

Frequently Asked Questions:

Q. Why should I use a crate for shipping freight?

Crates provide excellent protection for freight during transit. They shield items from damage caused by impacts, stacking, or exposure to weather. Crates are especially useful for shipping heavy, fragile, or valuable items like machinery, artwork, safes, and electronics.

Q. Are crates reusable for multiple shipments?

Yes, many crates are reusable if they remain in good condition. Durable materials like hardwood or plastic can withstand multiple shipments, but you should inspect the crate after each use to ensure it’s still sturdy and safe.

Q. How do I secure my items inside the crate?

Use internal bracing, padding, or straps to prevent the items from shifting during transit. Fragile items may need additional protection, such as custom foam inserts or bubble wrap. Ensure that all contents are immobilized to avoid damage.

Q. Do I need a custom crate for my shipment?

Custom crates are recommended for irregularly shaped, delicate, or high-value items. A custom-designed crate ensures a secure fit and provides maximum protection for unique shipments, such as industrial equipment, large artwork, or sensitive electronics.

Q. Can I rent crates for shipping instead of buying them?

Yes, some shipping and logistics companies offer crate rental services. Renting can be a cost-effective option for one-time shipments or businesses that want to avoid storage and maintenance costs for reusable crates.

Q. What happens to the crate after delivery?

Crates can either be disposed of, returned to the sender, or repurposed for other uses. Some companies offer reverse logistics to retrieve reusable crates. Always check with your carrier or customer about their preferred process

Advantages when using FreightCenter

25+ Years of Service

We have over 25 years of experience, as evidenced by our large network of professional carriers. Our knowledgeable team of shipping experts is ready to help you optimize your small business for the intricate world of logistics.

Customizable Shipping Options

Need a liftgate? No problem! Need to ship your products quickly? We got you covered! Our FreightCenter agents can offer you tailored solutions for your specific shipping needs, no matter what kind of small business you are.

Friendly Customer Support

Our customer support team has the answers to many of your shipping questions and concerns. We’re here to help you through every step of the shipping process, from initial inquiries to post-shipment issues.