CNC Machines

Shipping CNC Machines with Confidence

Moving CNC equipment takes more than muscle. It takes planning, precision, and the right logistics partner. FreightCenter makes shipping CNC machines safe, simple, and cost-effective—so your equipment arrives ready to perform.

Related Resources for CNC Machine Shipping

Heavy Equipment Shipping Machinery Shipping Flatbed Freight Shipping Freight Class Calculator Freight InsuranceShipping CNC Machines: Expert Freight Solutions

When you’re shipping a CNC machine, you’re not just moving freight—you’re transporting a core part of your operation. These machines are heavy, complex, and expensive, which means mistakes can cost time, money, and productivity. That’s why CNC machine shipping requires more than just finding a truck and loading it on a pallet. It requires a plan—and a partner who knows what they’re doing.

FreightCenter specializes in handling large, delicate, and high-value freight like CNC machines. Whether you’re shipping locally or across the country, our experienced logistics team helps you protect your investment, minimize downtime, and get your equipment where it needs to go—safely and on schedule.

Thousands of businesses trust FreightCenter to move their freight faster, smarter, and cheaper! From unbeatable rates to top-notch service, our customers are raving about their shipping success.

See why they keep coming back!

Award-Winning Service, Trusted by Shippers Everywhere!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

FreightCenter’s CNC Shipping Services

FreightCenter offers a full suite of CNC shipping solutions for industrial and commercial clients:

-

Rate comparison across national and regional carriers

-

Dedicated support from shipping experts

-

Crating and packaging assistance

-

Partial, full, or flatbed truckload shipping

-

Pickup scheduling and tracking tools

-

Delivery coordination with consignee

We don’t just quote your freight—we guide you through it.

Why Shipping CNC Machines Requires a Specialized Approach

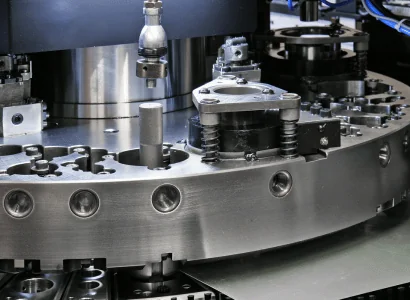

CNC (Computer Numerical Control) machines are known for their precision, but that same precision makes them sensitive to shock, vibration, and improper handling. These machines often have exposed components like spindles, wiring, and monitors, and some have internal fluids that must be drained before transport.

They’re also massive. A standard vertical CNC mill can weigh thousands of pounds, and lathes and routers may need flatbed or step deck trailers to accommodate their dimensions. In other words, CNC shipping isn’t a “book it and forget it” process.

It’s important to work with a logistics provider who understands:

-

Proper loading and securement techniques

-

Specialized equipment like air-ride trailers or liftgates

-

Carrier requirements for machinery

-

Packaging and crating options to prevent in-transit damage

-

Pickup and delivery site conditions (dock height, forklift access, etc.)

At FreightCenter, we’ve helped countless manufacturers, machine shops, and industrial resellers move CNC machines with confidence—because we treat every shipment like it’s our own.

Shipping a CNC machine isn’t like moving a pallet of boxes. These are high-value, precision-built investments that need to arrive intact, aligned, and ready to work. At FreightCenter, we approach every CNC shipment with that in mind. Whether you’re moving a compact desktop unit or coordinating the transport of a full-size 5-axis machine across the country, we act as a true logistics partner—blending experience, flexibility, and freight expertise to get your machinery where it needs to go, safely and efficiently.

If you're shipping a CNC router head, small milling unit, or replacement control boards, LTL (less-than-truckload) freight keeps costs down while ensuring secure handling. We tap into a vetted network of carriers who are familiar with machine tool shipments and know how to handle sensitive freight with care. That means proper bracing, accurate NMFC classification, and proactive coordination every step of the way.

Moving a full-sized CNC lathe or several machines at once? Full truckload (FTL) service gives you a dedicated truck with minimal handling—ideal for protecting heavy or oversized equipment. Whether it requires a dry van, step-deck, or flatbed with tarping, we secure the right setup based on your machine’s dimensions, weight, and load requirements.

Downtime can cost thousands per day. If you’re facing tight production deadlines or just can’t afford delays, we offer expedited freight options designed for CNC machine deliveries. Think team drivers, direct routing, and prioritized transit—all coordinated by our logistics pros with real-time updates available from pickup to delivery.

Some CNC shipments need more than just wheels. FreightCenter’s specialized freight services handle jobs that call for rigging, cranes, escort vehicles, or international documentation. Whether it’s a vertical machining center that can’t be tilted or an export-bound machine that needs custom crating and ISPM-15 certification, we line up the right resources for a safe, compliant move.

Pro Tips: Avoid These CNC Shipping Mistakes

Even experienced shippers can overlook critical steps. Here are some tips to avoid problems:

-

Label everything. Clearly mark “fragile,” “do not stack,” and top/bottom indicators on crates.

-

Confirm pickup and delivery details. Especially suite numbers, contact names, and phone numbers.

-

Check for required accessorials. If a liftgate or inside delivery is needed, request it in advance.

-

Insure high-value machines. Standard freight liability doesn’t cover the full cost of CNC equipment. Ask about additional freight insurance.

CNC Machine Shipping FAQ

Q. What is the best way to ship a CNC machine?

The best way to ship a CNC machine is through freight shipping, typically using full truckload (FTL) or partial truckload (PTL), depending on the size and weight. FreightCenter helps you choose the right method based on your machine’s specifications and destination.

Q. How do I prepare a CNC machine for shipping?

To prepare a CNC machine for shipping, you should disconnect power, drain fluids, secure moving parts, and properly crate or palletize it. FreightCenter can connect you with crating services if needed.

Q. How much does it cost to ship a CNC machine?

CNC machine shipping costs vary based on machine size, weight, distance, freight class, and delivery requirements. You can get a free quote through FreightCenter’s rate calculator or by speaking with a shipping expert.

Q. What freight class is a CNC machine?

Most CNC machines fall under NMFC freight class 85–125, depending on density and packaging. FreightCenter can help you classify your machine accurately to avoid reclass charges.

Q. Can I ship a used CNC machine?

Yes, both new and used CNC machines can be shipped safely. Make sure to inspect and photograph the equipment before shipment for insurance purposes.

Q. Is insurance included when shipping CNC machines?

Carrier liability coverage is included, but it may not fully cover the machine’s value. FreightCenter offers additional cargo insurance for full protection.

Q. Do I need a liftgate to deliver a CNC machine?

Because of their weight and size, CNC machines typically require a dock or forklift. If a liftgate is necessary, FreightCenter can arrange that with your carrier.

Q. Can I ship a CNC machine internationally?

Yes, international CNC shipping is available. FreightCenter helps with documentation, customs clearance, and arranging ocean or air freight when needed.

Q. How long does CNC machine shipping take?

Transit times depend on the origin, destination, and service type. Domestic shipments may take 2–7 business days. Expedited services are available upon request.

Q. What are the risks of shipping a CNC machine?

Risks include tipping, vibration damage, or mishandling. FreightCenter works with carriers that specialize in heavy machinery to reduce these risks.

Q. Do I need to crate my CNC machine for shipping?

Crating is highly recommended for protection. Some carriers may require it. FreightCenter can connect you with trusted crating services nationwide.

Q. How do I choose the right carrier for CNC machine shipping?

FreightCenter matches your shipment with vetted carriers based on experience with heavy equipment, transit time, and cost efficiency.

Q. Can I track my CNC shipment in real-time?

Yes. FreightCenter offers real-time shipment tracking and proactive updates, so you know where your CNC machine is every step of the way.

Q. What accessorial charges should I look out for?

Charges may apply for liftgate delivery, residential access, limited access locations, or reclassification. FreightCenter helps you understand and plan for these ahead of time.

Q. Why choose FreightCenter to ship my CNC machine?

With over 25 years of experience, a wide network of carriers, and dedicated freight experts, FreightCenter offers custom, cost-effective, and secure shipping solutions for CNC machinery.

Fascinating Facts About CNC Machines That Most People Don’t Know

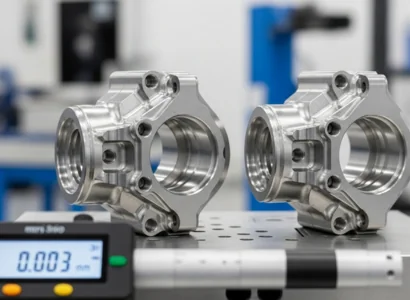

CNC Machines Can Produce Identical Parts to Within Microns

CNC machines are known for their exceptional precision. Many can hold tolerances tighter than the thickness of a human hair, which is about 70 microns. In fact, some advanced CNC mills and lathes can consistently achieve tolerances as tight as ±5 microns (0.005 mm). This extraordinary level of accuracy is why CNC machining is widely used in industries like aerospace, medical, and defense manufacturing, where even the smallest deviation can lead to critical failures.

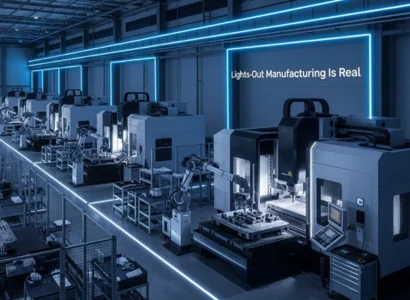

They Can Run 24/7—Lights-Out Manufacturing Is Real

CNC machines don’t need coffee breaks. Once programmed and set up, they can run unmanned around the clock—this is called “lights-out” machining. Many manufacturers run machines overnight or through weekends to boost productivity without hiring additional staff.

Modern CNC Machines Can Communicate With Each Other

Thanks to Industry 4.0 innovations, CNC machines can now be integrated into smart factory networks. They use sensors, Wi-Fi, and software to monitor performance, report errors, and even automatically adjust cutting paths based on real-time feedback—all without human intervention.