Shipping Injection Molding Machines

Ship Injection Molding Machines Seamlessly

At FreightCenter, we customize every shipment to meet your needs, while ensuring quality, safe, and secure delivery to any location.

Explore Related Shipping Options:

Shipping Machine Parts Shipping Plastic Resins and Polymers Shipping Equipment Shipping Plastics and Plastic ProductsSeamlessly Ship Injection Molding Machines with FreightCenter

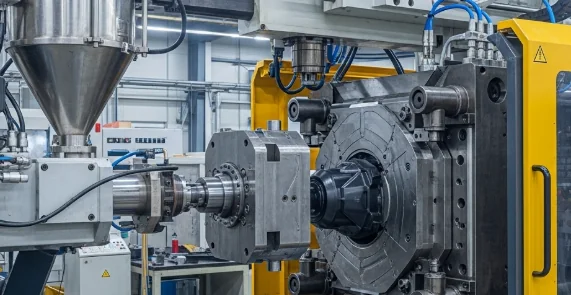

Shipping injection molding machines require specialized handling due to their high-value, size, and need for protection from outside elements. Whether shipping a hydraulic, electric, or hybrid machine, this equipment requires planning and expertise to ensure they arrive safely and securely to their intended destination.

FreightCenter is the unrivaled choice when it comes to choosing a 3PL to partner with for shipping injection molding machines. We connect our customers to a network of top, vetted carriers, customer support for any questions, and dependable delivery services. With our 25+ years of expertise in the industry, you can put your trust in us to ensure your injection molding machines are handled with the utmost care, seamlessly transported, and efficiently delivered.

Thousands of businesses trust FreightCenter to move their freight faster, smarter, and cheaper! From unbeatable rates to top-notch service, our customers are raving about their shipping success.

See why they keep coming back!

Award-Winning Service, Trusted by Shippers Everywhere!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

Choosing FreightCenter For Injection Molding Machine Shipping

Specialized Carrier Network:

FreightCenter partners with a vast network of freight carriers that specialize in heavy equipment shipping, including injection molding machines. This allows us to match your shipment with the right equipment – flatbeds, step decks, or climate-controlled trailers – based on your specific needs.

Real-Time Tracking Tools:

Stay informed every step of the way, from pickup to delivery. Our advanced shipment tracking tools and dedicated support team keep you updates on the status of your machine so you know exactly where it is and when.

Expert Logistics Support :

Our freight experts understand the complexities of moving large, high-value manufacturing equipment. We’ll help with packaging recommendations, permits, any liftgate services, and route planning that you need to avoid delays or damage.

How to Properly Prepare and Package Injection Molding Machines for Freight Shipping

Shipping injection molding machines requires careful preparation, proper packaging, and the right logistics strategy to ensure safe and efficient transport. FreightCenter can assist in ensuring you take the proper steps to protect your equipment:

Pre-Shipment Preparation

Full Inspection

First, perform a full inspection of the machine for any existing wear or damage. Take clear photos of the machine and record machine specs, configurations, and serial numbers.

Drain Fluids and Safely Disconnect

Completely drain any hydraulic oil, coolant, and water to prevent leaks or spills during transit. Then, shut off and disconnect all power, electrical, and pneumatic lines.

Secure Key Components and Remove Loose Parts

Lock down the injection and clamping unit, and then secure or remove the mold. Take off any detachable items to prevent damage or loss during transit.

Packaging Injection Molding Machines

Protection Materials

- Use shrink wrap for overall protection.

- Seal open ports with caps or plugs.

- Wrap sensitive parts in foam padding or bubble wrap.

- Apply ant-rust oil like WD-40 or utilize VCI bags for corrosion protection, especially if shipping via ocean freight.

Crating and Palletizing

- Use a custom-built wooden crate or heavy-duty steel skids.

- Anchor the machine securely using clamps or bolts.

- Add shock-absorbing padding for sensitive areas.

- It’s important to include lifting lugs, center-of-gravity markings, and handling instructions.

Waterproofing

- Seal the crate with plastic sheeting or shrink wrap.

- Use desiccant packs to manage moisture inside the crate.

Disassembly (If Needed)

- Very large injection molding machines may require partial disassembly to meet shipping size or weight restrictions. Reassembly is typically done at the destination.

To create value for our customers by delivering customized shipping solutions that meet their unique needs and to fulfill shipping demands from simple to complex with expertise, guidance and ingenuity.

Accurate freight classification is key to receiving fair and transparent shipping rates. Our easy-to-use Freight Class Calculator helps you determine the correct freight class for your shipment based on size, weight, and product type. This tool simplifies the quoting process and ensures you avoid costly reclassification fees.

Your raw materials are valuable, and protecting them during transit is essential. FreightCenter offers customizable freight insurance options to give you peace of mind. In the rare event of damage or loss, our insurance plans ensures you're covered, minimizing risks and financial impacts.

Cross borders seamlessly! Our international shipping services connect you to top carriers for easy ocean, air, and cross-border freight. Whether importing or exporting, we handle the logistics so your injection molding machine arrive safely and on time.

Shipping to a location with limited access? Limited access pickup and delivery ensures your freight reaches places like urban areas or restricted warehouses. Perfect for hard-to-reach destinations that require extra coordination.

We Handle Injection Molding Machines with Precision

At FreightCenter, we understand the importance of reliable shipping to your manufacturing operations, especially when it comes to transporting injection molding machines. Whether you’re moving a single unit or an entire production line, we’re the trusted choice for heavy, oversized equipment shipping.

Our extensive network of specialized carriers ensures safe and on-time delivery, regardless of size, weight, or destination. With industry expertise and cutting-edge logistics technology, we simplify the shipping process from start to finish, helping you save time, reduce costs, and avoid delays.

Let us handle the complex details, from carrier coordination to real-time tracking and competitive pricing. Contact our expert agents today at (800) 716-7608 and ship your injection molding machine with confidence. FreightCenter is your reliable partner in freight transportation.

FAQ: Shipping Injection Molding Machines

Q. How do I obtain a quote for shipping injection molding machines with FreightCenter?

Getting a quote is easy. To get a personalized quote for shipping injection molding machines, provide us with your shipment details like weight, dimensions, and the pickup and drop-off ZIP codes, and our FreightCenter experts will assess your needs and provide you with a detailed quote with the most cost-effective and efficient delivery method.

Q. What is the best way to ship injection molding machines with FreightCenter?

Injection molding machines can be shipped in multiple ways depending on your shipping needs. We offer FTL, Ocean Freight, Heavy Haul, and Expedited shipping services.

Q. What types of injection molding machines can I ship with FreightCenter?

You can ship any type of injection molding machine with FreightCenter, including hydraulic, electric, and hybrid injection molding machines.

Q. How should I package my injection molding machine for transport?

You should package your machine into a custom crate, adding shrink wrap for general surface protection, using shock-absorbing padding and other materials for sensitive components, ensuring it’s secure.

Q. Can I insure my injection molding machine shipment with FreightCenter?

Yes, you can. While it isn’t required, FreightCenter highly recommends insuring your injection molding machine shipment. Not only does insurance provide peace of mind, but it also protects your shipment in the rare case of damage or loss during transit.

Q. How can I track my injection molding machine shipment with FreightCenter?

Our advanced tracking systems allow you to monitor the status of your shipment from pick-up to delivery. All you need is your tracking number.

Q. What kind of freight equipment is used to transport injection molding machines with FreightCenter?

Depending on the machine’s dimensions and weight, FreightCenter recommends flatbed trailers, step deck trailers, or dry vans if size permits. FreightCenter will match your shipment to the most suitable transport option.

Q. Do I need to disassemble my injection molding machine for shipping?

In some cases, partial disassembly is necessary to comply with height, width, or weight restrictions. Our logistics team will help you determine if disassembly is required and coordinate transport for multiple components, if needed.

Q. How much does it cost to ship an injection molding machine with FreightCenter?

Shipping costs vary based on machine size, weight, distance, transport method, and additional services like insurance. We provide free quotes to help you compare rates from top carriers and find the most cost-effective option.

Q. What safety measures are used during transit for injection molding machines?

Our carriers who are experienced in heavy machinery transport safety protocols, use heavy-duty straps, chains, clamps, and securement systems to keep the machine stable during transport.

Q. Can FreightCenter helps with permits for oversized injection molding machine shipments?

Yes, FreightCenter assists in obtaining the necessary oversize load permits. If your machine exceeds legal height, width, or weight limits, we ensure all transport regulations are met to avoid fines or delays.

Q. How far in advance should I schedule a shipment with FreightCenter?

We recommend booking your injection molding machine shipment at least 3-7 days in advance for domestic moves and 2-3 weeks for international shipping.

Q. Does FreightCenter offer white-glove or on-site loading services?

Yes, we offer white glove services, which include on-site loading and liftgate service. These services are ideal for delicate or high-value injection molding machines.

Q. Can FreightCenter ship multiple machines at once?

Absolutely. FreightCenter can coordinate the consolidated shipping of multiple injection molding machines or related equipment on a single shipment.

Q. Does FreightCenter provide customer support for injection molding machine shippers?

Yes, FreightCenter offers dedicated shipping specialists to help you plan, book, and manage your injection molding machine shipment.

Three Things You Didn't Know About Shipping Injection Molding Machines

There Are Different Types of Machines

Injection molding machines come in different types such as hydraulic, electric, and hybrid. The different types of machines can affect their design, and hence, their shipping needs. Check with your freight agent to find out what your shipment requires.

Injection Molding Machines Require Environmental Protection

When shipping injection molding machines, it's important to ensure it is protected from the elements. Beyond physical damage during transit, it requires protection from humidity, salt, and dust, especially when being shipped by sea.

Meeting Customs Clearance and Having Correct Documentation is Important

Many injection molding machines are built and shipped internationally, so it's important to ensure it meets all shipping regulations, customs clearance, and export/import procedures. Your expert freight agent will ensure you meet all the requirements when shipping internationally.