Packaging Machinery Equipment

Ensuring Safe and Secure Shipping

Whether you're shipping a single shrink wrapper or an entire production line, properly packaging machinery equipment is critical for a smooth, damage-free delivery. Get expert help from FreightCenter packaging and shipping your machinery equipment safely and affordably.

More Information for Packaging Machinery Equipment

FreightCenter's Guide to Freight Packaging Shipping Labels Heavy Haul ShippingMore Information for Packaging Machinery Equipment

Shipping Generators Shipping Metals and Metal ProductsPackaging Machinery Equipment Made Easy

Shipping packaging machinery and equipment is not your typical freight job. These items can be heavy, irregularly shaped, sensitive to impact, or may require special handling and documentation. Whether you are transporting a shrink wrapper, cartoner, case sealer, or a large industrial conveyor system, it is crucial to ensure that the packaging and shipping are done correctly to protect your investment.

This guide will explain what constitutes packaging machinery and equipment. You’ll also learn how to prepare it for transport, the associated costs, and how FreightCenter can simplify the process for you.

Thousands of businesses trust FreightCenter to move their freight faster, smarter, and cheaper! From unbeatable rates to top-notch service, our customers are raving about their shipping success.

See why they keep coming back!

Award-Winning Service, Trusted by Shippers Everywhere!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

Why Choose FreightCenter for Your Machinery Equipment Shipping Needs?

Expertise in Industrial Freight: With over 25 years of freight shipping experience, we have a deep understanding of packaging machinery and equipment. We regularly collaborate with manufacturers, distributors, and operations managers to safely transport sensitive equipment while ensuring high-quality service.

Tailored Freight Solutions: From LTL to FTL, and from heavy haul to white glove services, our team matches your equipment with the right carrier. We customize your booking to meet your specific shipping needs, ensuring your equipment is delivered in the right condition and at the right time.

Packaging Support: Need help with prepping your shipment? Our team offers guidance on proper machinery packaging, or we can connect you with third-party crating or palletizing partners who can do the hard work for you.

Discounted Carrier Rates: Leverage our volume pricing for competitive quotes with top national and regional carriers. All you need to do is use our online quoting tool to generate and select from reduced rates by our carrier network.

End-to-End Support: From quote to delivery, our team is here to help you plan and manage every step of the shipment. We’ll track your shipment, answer questions about the freight shipping process, and solve issues both during and after your shipment is complete.

What Qualifies as Machinery Equipment?

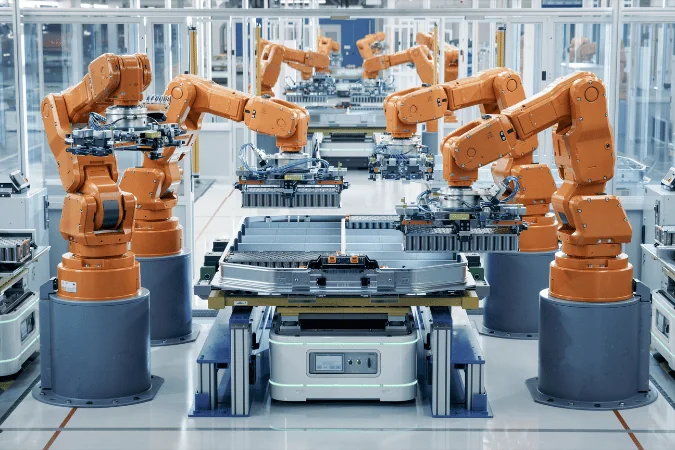

“Machinery equipment” refers to large, industrial-sized machines used for manufacturing, processing, agriculture, or construction. Common examples include:

- CNC machines

- Milling machines

- Lathes

- Compressors

- Generators

- Pumps

- Conveyor systems

- Hydraulic presses

- Drills and saws

- Assembly line equipment

These powered mechanical devices often require disassemblment and securement before they are packaged and transported to their destination. As they are frequently heavy and bulky machines, they will also require additional services, such as heavy haul shipping, to ensure proper delivery without compromising the shipment’s integrity.

Note that the shipper is responsible for packaging the machinery equipment themselves. This means that when the carrier arrives, your freight must be fully packaged, labeled, and presented with the correct documents to the carrier; otherwise, the driver will leave without your freight. If you are concerned about packaging your equipment yourself, FreightCenter can guide you on how to do it properly or connect you with third-party packaging specialists who can pack your machinery for an additional cost.

Proper packaging protects your machinery equipment from vibration, weather, and impact during shipping. Here's how to do it right:

Review your machinery equipment. You'll need to take measurements (L x W x H) and weigh your equipment. You'll also need to determine if any parts will need to be disassembled and packaged separately for safer transport. If your equipment is too small for a full truckload, also consider transporting with LTL freight shipping, though note that you may need sturdier packaging to keep your equipment safe.

What packaging you use for your machinery equipment depends on the equipment itself. Wooden crates, for example, offer superior protection for high-value or fragile components, while just placing it on a pallet is fine if your machinery is sturdy and has a flat base. Regardless of your equipment, you should shrink wrap and strap down parts to prevent shifting, and add internal cushioning like foam padding.

Labeling your shipment is an underrated but essential step in freight packaging. Ensure that you attach a packing slip securely and visible to anyone looking in at the trailer. You will also need specialized labels like "Heavy Equipment", "Do Not Stack", and "Fragile" if applicable.

Documentation during freight shipping assists in the event of damage or loss during transit. Take photos before and after packaging your shipment, and keep a checklist of removed parts for both you and the receiver. You may also want to keep a list of protective materials used in the packaging to further help in an insurance claim.

FreightCenter Services for Machinery Equipment Shipping

FreightCenter is always ready to help you with packaging and shipping your machinery equipment. Some of the services we offer that can help you with your equipment include:

- Packaging Support: We can connect you with third-party crating services that can package your freight for you or provide guidance on how to do it yourself.

- Heavy Haul Shipping: Oversized loads require specialized packaging, as well as permits and escorts. We’ll help you arrange all of this and more.

- Flatbed Shipping: For odd-shaped or oversized equipment, our flatbed shipping options are perfect for you.

- Inside Pickup and Delivery: This service enables the driver to assist you in relocating your freight within your business or home, for an additional fee.

- Liftgate Services: Drivers will provide a liftgate if you are unable to load your equipment in by yourself or don’t have a loading dock.

If you’re ready to get help with packaging machinery equipment, call (800) 716-7608 to speak with a FreightCenter agent or use our free online quoting tool to start shipping with FreightCenter today!

Frequently Asked Questions about Packaging Machinery Equipment

Q. What qualifies as “machinery equipment” for freight shipping?

Machinery equipment refers to mechanical devices or assemblies used in industrial, agricultural, or construction operations. This includes items such as CNC machines, lathes, generators, compressors, milling machines, conveyor systems, and other related equipment. These machines often require special handling due to their size, weight, or fragility. If you’re unsure whether your item qualifies as machinery equipment, FreightCenter’s team of logistics experts can help evaluate your freight and classify it correctly for transport.

Q. Can FreightCenter help me package my machinery?

Yes, FreightCenter can guide you through the entire packaging process for your machinery shipment. While we don’t physically package the equipment ourselves, we partner with professional crating and packaging service providers across the U.S. If you need a custom crate built, foam padding installed, or guidance on best practices for bracing heavy equipment, we’ll coordinate the right resources or walk you through how to do it properly based on your shipment details.

Q. Is crating always required?

Crating is not always mandatory, but it is strongly recommended for certain types of machinery, especially high-value, fragile, or irregularly shaped items. Crating provides a rigid outer structure that protects your equipment from impact, vibration, and environmental exposure. In some cases, insurance carriers may require crating to validate coverage. FreightCenter can help you determine whether crating is necessary for your shipment and recommend reliable providers.

Q. What if I don’t know how to measure my equipment?

Accurate measurements are crucial for obtaining accurate freight quotes and selecting the right carrier or service. If you’re unsure how to measure your machinery, start by measuring the length, width, and height of the item in its packaged state, including the crate or pallet (if applicable). Also note the weight and whether the equipment is stackable. FreightCenter’s freight agents can walk you through what measurements are needed, and our website offers tools to help you calculate freight class and dimensional weight.

Q. How much does packaging cost?

Packaging costs vary based on factors such as size, materials, complexity, and whether professional services are used. For example, building a custom wood crate can cost anywhere from $150 to $ 1,000 or more, depending on its dimensions and construction. Palletizing and shrink-wrapping might only cost $50–$200. If you need help budgeting, FreightCenter can provide estimates based on your shipment and help you find packaging services that match your needs and price range.

Q. Can you ship disassembled machinery?

Yes, shipping disassembled machinery is often a smart move. It can lower shipping costs by reducing the overall footprint and help prevent damage by isolating delicate components. When shipping in parts, it’s important to label each item clearly, secure them properly, and provide detailed packing lists. FreightCenter can help you plan how to organize and label disassembled parts so that they’re packaged efficiently and received without confusion.

Q. Do I need to remove fluids from my equipment before shipping?

In almost all cases, yes, especially if you’re shipping items like generators, compressors, engines, or hydraulic equipment. Shipping equipment containing oil, fuel, or other fluids can pose a safety hazard and may violate carrier policies. Fluids can also leak and damage other freight. FreightCenter recommends draining all fluids and securing any hoses or reservoirs prior to shipment. If you’re unsure about how to prepare your equipment, we can guide you through the safety protocols and documentation requirements.

Q. What if my equipment is too large for a crate?

If your machinery is oversized or has a shape that makes crating impractical, don’t worry; specialized solutions are available to accommodate these needs. Flatbed trailers, step-deck trailers, and heavy-haul equipment are commonly used to transport large or irregularly shaped machinery. These shipments require additional securement methods, such as chains, tarps, and specialized permits. FreightCenter collaborates with carriers that specialize in oversized freight, helping to arrange the necessary equipment and permits for safe delivery.

Q. Is insurance available for machinery shipments?

Absolutely. Because machinery equipment tends to be high in value, freight insurance is strongly recommended. Most standard freight shipments come with limited liability coverage from the carrier; however, this coverage is often insufficient to fully replace damaged machinery. FreightCenter offers optional, third-party freight insurance through third-party providers that can cover the full value of your equipment. Our agents can help you select the right policy and ensure you’re appropriately protected.

Q. Can you pick up from a job site or warehouse?

Yes, FreightCenter can coordinate pickups from job sites, warehouses, factories, or other commercial locations. When booking, please provide us with the exact address and any site-specific restrictions. If there are challenges, such as limited access, no loading dock, or specific timing requirements, we’ll work with the carrier to ensure your pickup goes smoothly. Our goal is to match the right equipment and service to your specific shipping environment.

Q. What if I don’t have a forklift or loading dock?

If your location doesn’t have a loading dock or forklift, we can arrange for liftgate service or white glove delivery depending on your needs. A liftgate enables the driver to lower the equipment from the truck to ground level, which is essential for delivering heavy machinery to residential, retail, or smaller industrial locations. Just let FreightCenter know ahead of time, and we’ll add the right accessorials to your booking.

Q. How do I label machinery freight?

Each item in your shipment should be clearly labeled with the destination address, bill of lading (BOL) number, and any special handling instructions (e.g., “Fragile,” “Do Not Stack,” or “This Side Up”). If your machinery has been disassembled, label each crate or package with its contents and reference numbers to facilitate easier reassembly. FreightCenter provides shipping documents and can guide you on what labels to include and where to place them.

Q. What’s the fastest way to ship machinery equipment?

If speed is the priority, expedited services are your best options. These services prioritize your shipment and reduce transit time by minimizing terminal stops. Expedited services may incur higher costs but are ideal for urgent installations, breakdown replacements, or time-sensitive manufacturing operations. FreightCenter collaborates with a network of carriers that provide flexible, expedited options specifically designed for shipping heavy equipment.

Q. Is tracking available during shipment?

Yes, tracking is available for nearly all shipments booked through FreightCenter. You can track your machinery equipment in real time using your FreightCenter account dashboard or by using the tracking link provided in your confirmation email. For higher-value machinery, our agents can also provide proactive updates and assist in monitoring the shipment’s status from pickup to delivery.

Q. Can I get a real-time quote online?

Yes! FreightCenter’s free quote tool lets you enter your shipment details—including dimensions, weight, origin, and destination—and instantly receive real-time rates from top freight carriers. For machinery equipment shipments, we recommend speaking with a freight agent at (800) 716-7608 if your equipment is oversized, requires special handling, or has unique packaging needs. Our team can help you compare options and ensure your quote reflects all necessary services.

Packaging Tips for Common Machinery Types

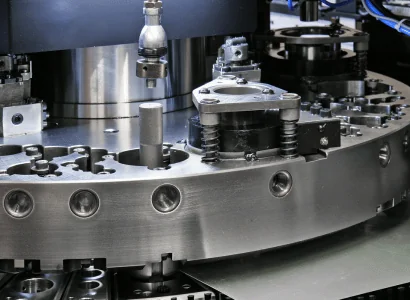

CNC Machines

CNC machines contain delicate internal components and precision-calibrated parts that can be damaged by vibration or impact during transit. Proper packaging minimizes movement and keeps sensitive elements secure. Use vibration-dampening pads inside the crate to absorb shocks during transportation. Secure all moving parts with strong straps or rigid braces to prevent shifting while in transit.

Compressors & Pumps

Compressors and pumps often contain fluids and are sensitive to leaks or pressure changes during shipping. Proper packaging prevents spillage, corrosion, and structural damage. Drain all fluids before packaging to avoid leaks that could damage the machine or other freight. Crate the equipment using internal foam padding and a moisture barrier to shield it from environmental exposure.

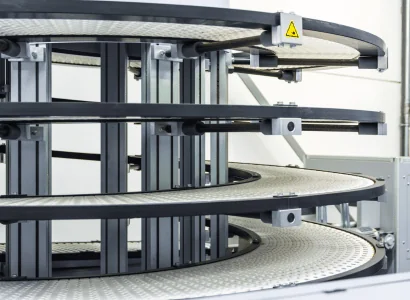

Conveyor Systems

Conveyor systems can be long, bulky, and often consist of multiple interconnected sections that can easily be bent or misaligned. Disassembly and protective packaging help prevent structural damage and simplify loading. Disassemble the conveyor into manageable sections when possible to make packaging and transport more efficient. Label each part clearly and secure it with protective foam and industrial wrap to prevent scratches and misplacement.